Recently, heat transfer is widely used in garment printing.And in the market,we always see hot peel film and cold peel fim,even now also with warm peel film,but which one is best? Here we can do a analyze from different aspects as below:1.Composition of the ingredient.Hot peel.In order to achieve the effect of quick tearing,the main component of the release layer is wax, which is very unstable,not easy to melt and apply.For example,when we apply a release layer on the pet film,if a large amount of wax is applied,it is difficult to ensure uniformity.Cold peel.The release layer is dominated by the chemical component silicon,and the stability is much better than that of wax,which is easier to apply to the film,and the cold peel film is relatively stable.The cold tear film market is very mature,and Korean hot stamping is the principle of cold tear film.

2. Pressing temperature and time.

Hot peel usually required pressing temperature is generally between 140-150°C and 5-10 seconds. Cold peel usually required pressing temperature is higher than that of the hot tear film, generally at 150-170°C,10-20 seonds, which needs to be determined according to the specific situation.

3.Cooling time or waiting time.

1. Hot peel: 2-3 seconds can be satisfied to tear.

2. Cold peel: It maybe about 30 seconds can tear film.

4.Glossy and stretching

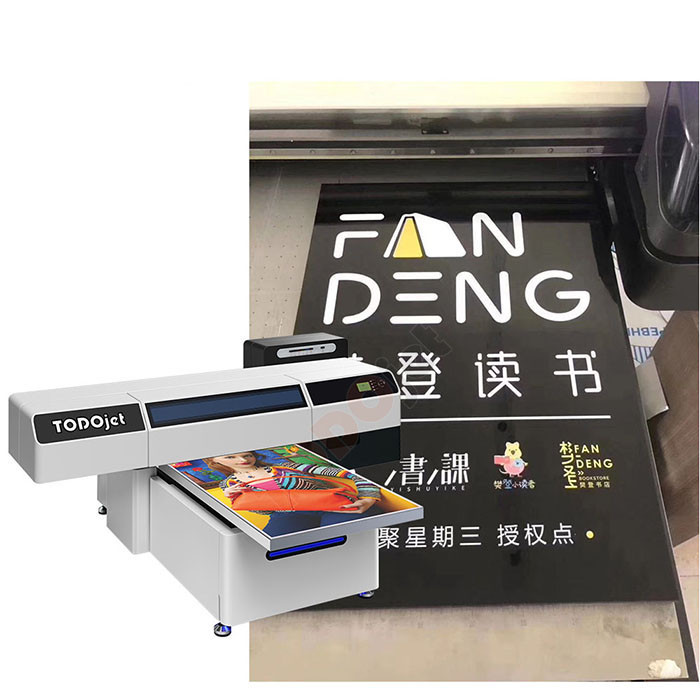

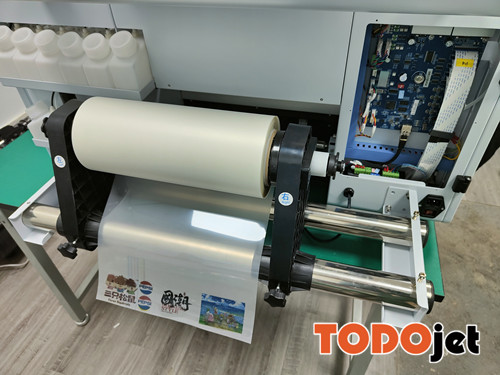

Someone said the color looks more vivid after hot peel,but from our testing,there is no much difference.But the stretchability is different according to different supplier.Here TOODjet can offer you one-stop solution of powder, film and pigment ink.

5.Washing fastness

Hot peel. The specifications of the hot tear engraving film on the market are generally 60cm wide, and after the hot heat is torn off, its adhesive layer adopts a water-based back coating process, if it is not torn off in time, the cooled glue will stick to the clothing, causing the tearing difficulty between the clothes and the film. Moreover, the water-based glue layer, for long-term water washing, fastness can not be guaranteed.

Cold peel. The specification of cold tearing is generally 50cm wide, and then it is torn off after being cooled, and its adhesive layer adopts oil-based back-coating process, and the fastness is better.

6.Application

From fabric materials,some special fabrics, such as tarpaulin, coated cloth and other fabrics, which are very thin themselves, and the coating is a gelatinous material, which can only be used cold-peel film, then it has enough attribute reduction time to ensure its adhesion and flatness after heat press (it is easy to wrinkle and warp if use hot-peel, resulting in material scrapping). Other rough texture fabric such as canvas and flannelette suitable for cold-peel.

From printing area, the hot peel film is more suitable for large patterns such as the front chest and back, while the cold peel film is suitable for thinner lines such as the back collar and letters.

Generally speaking, hot peel and cold peel with its own advantages such as the hot peel maybe can save your labor time if you have large-quantity order.Anyway you can choose according to your demand. Whether you choose hot peel or cold peel,the most important points need to be noticed,which are temperature, time and pressure.