What Is Direct-To-Film Printing?

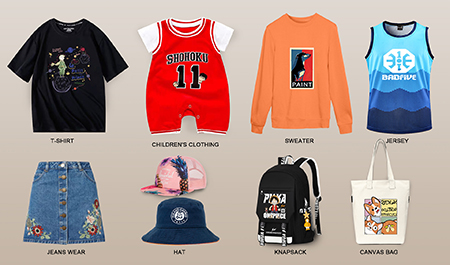

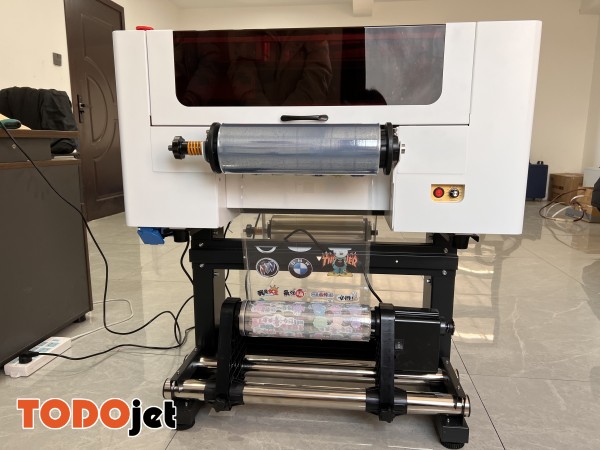

Direct-to-film printing is an advanced craft , which directly transfer designs from films to fabrics.The process of DTF printer is an innovative achievement compared to screen-printing.Faster and convenient new operation method.The primary feature of DTF is that the DTF printing machines are compatible with various materials and produce colorful ,durable and rich designs.

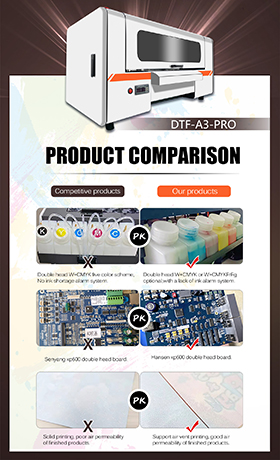

Direct-to-film printing is an advanced craft , which directly transfer designs from films to fabrics.The process of DTF printer is an innovative achievement compared to screen-printing.Faster and convenient new operation method. DTF printer makes the digital printing process faster and more efficient.At the same time,the price is affordable.DTF Printer can enable vibrant color prints on your t-shirts. You can print on light and dark fabrics.The T-shirt printing machine is compatible with various materials like polyester, spandex, cotton, leather, and more.It features dual EPSON i3200-A1 for both CMYK and white.The direct-to-film operation process is a brilliant improvement in the printing industry.It takes the small production company to a higher level, making heat-press printing faster and easier.

Feature of DTF Printer

1. The primary feature of DTF is that the DTF printing machines are compatible with various materials and produce colorful ,durable and rich designs.

2.This kind of DTF Printer involves using PET films,sticky powder and 5-color ink tanks(Fluoresent color for option).

3.The process eliminates any pretreatment requirement and works on light and dark fabrics.

4.DTF printing reduces the heavy investment cost.

5. An automatic ink circulating system to prevent white ink precipitation and reduce clogging.

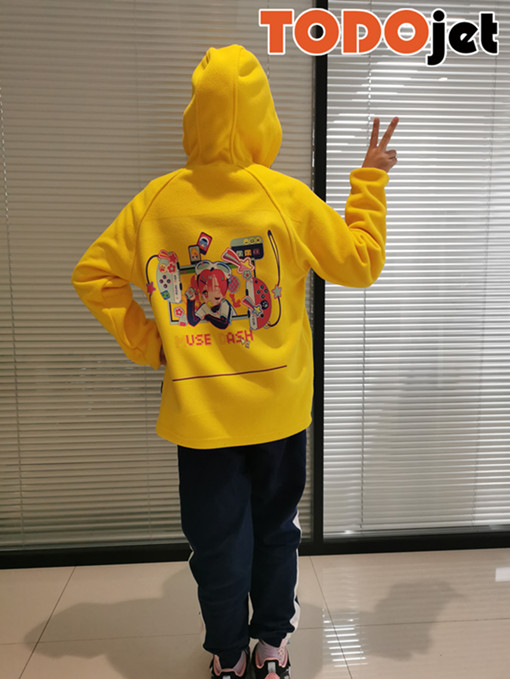

Finished product display

Package

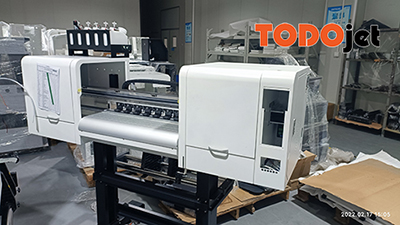

ABOUT TODOjet

TODOjet is engaged in R&D, production and sale of digital printers. we specializing in research, manufacture, sale and service of wide-format printer,UV flatbed printer, textile printer,fabric digital inkjet printing machine and related consumables.

By cooperating with world famous printhead manufacturers and software suppliers, we integrate exquisite and practical technology into our products. With 12 years experiences in printing filed, TODOjet can offer you printers with high quality, professional package and good service.Up to now,our printers have exported to many overseas market such as Europe, South America, Southeast Asia and Africa.