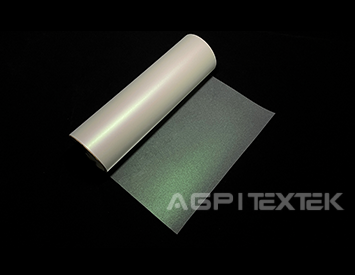

Hot selling xp600 Printhead Dtf Printer For T-shirt and Cheapest Shake Powder of A3 Rolling Pet Clear Film with low price

TODOJet textile printer-new equipment in 2023.

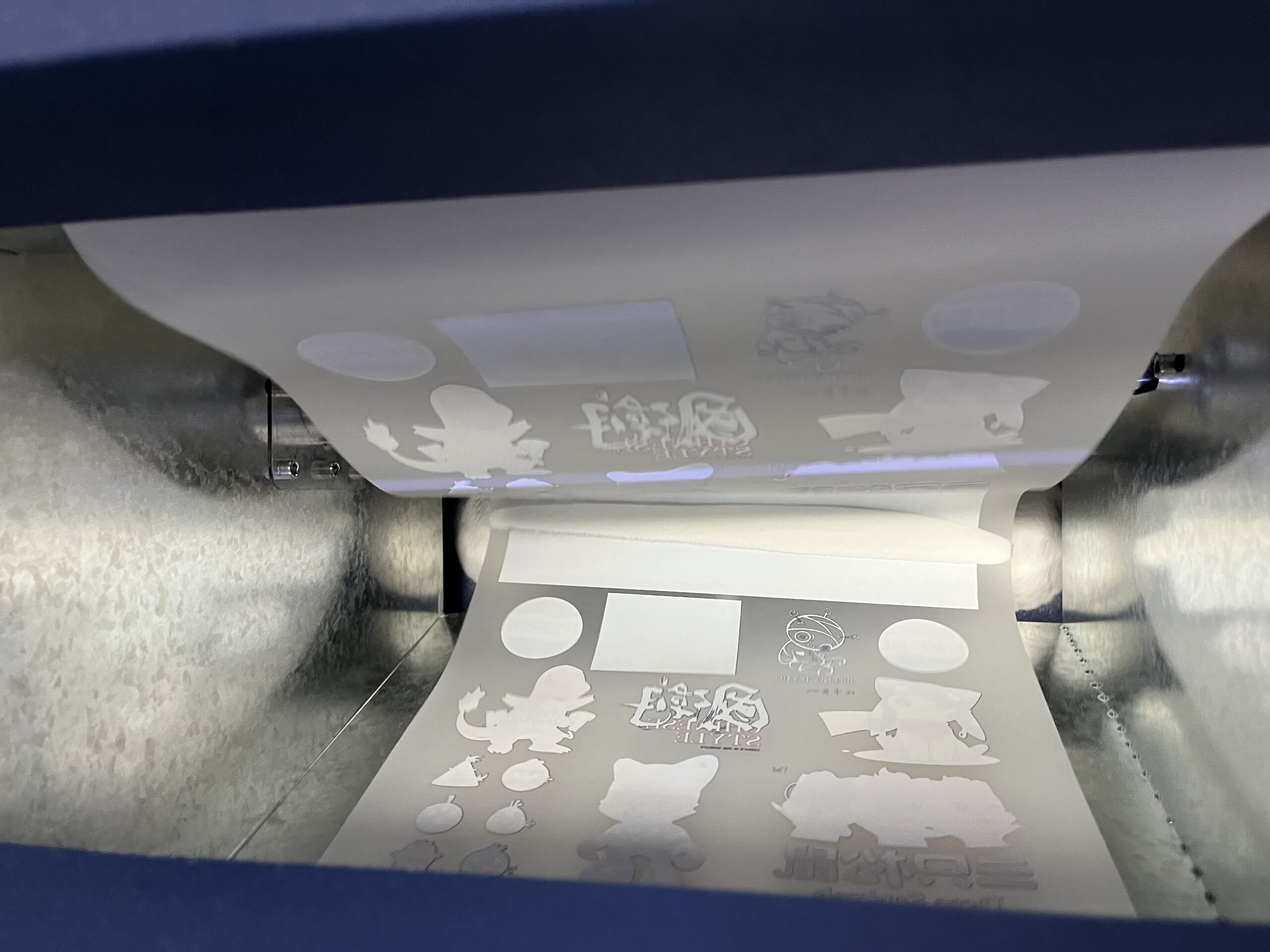

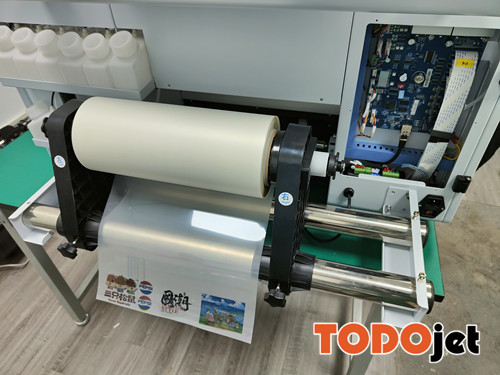

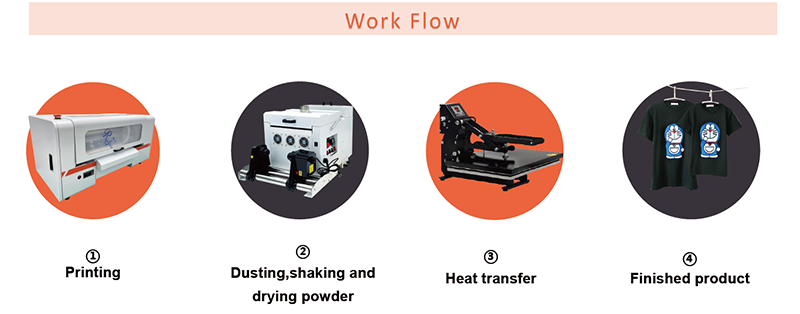

DTF technology has been around for several years, but it became very common in the last year. The essence of this technology is to use textile pigment ink to directly print on a special PET film. After printing, the film enters the powder shaker, sprays special powder on the film, and then the film is dried after spraying, and then the film with the print pattern is wound on the receiving device . This technology allows you to print images at high speed without placing the product on the desktop alone, you just need to place the film, create a layout with the image and start printing.

Type: Inkjet Printer

Applicable Industries: Garment Shops, Home Use, Printing Shops, Advertising Company

After Warranty Service: Video technical support, Online support

Local Service Location: Egypt, Turkey, Italy, Pakistan, Chile, UAE, Colombia, Algeria

Showroom Location: Egypt, Turkey, Italy, Spain, Romania, Australia

Plate Type:DTF Printer

Usage: Cloths Printer, film printer

Automatic Grade: Automatic

Color & Page:Multicolor

Voltage:110v-220v

Certification: CE

After-sales Service Provided: Online support, Video technical support

The paint offset heat transfer process is to directly print water-based paint ink and white ink on the medium of PET film. The printer is connected to a duster. After the PET film is printed, it goes through the duster and sprinkles hot melt adhesive powder on the corresponding pattern. Finally, dry and fix the color and roll it in one step.

A3 DTF Pro Printer:

| Print head | 2pcs Epson XP600 heads |

| Print speed | 3-10sqm/h |

| Accuracy | 360*2400dpi/360*3600dpi/720*2400dpi |

| Ink type | Pigment ink/Transfer film ink |

| Media Maximum Width | 32cm width |

| Media thickness | 1mm adjustable |

| Media type | PET film A3 size sheet / 30cm width roll |

| Heating system | Auto constant temperature drying system |

| Temperature | 160-170 cold/hot to tear |

| RIP software | Maintop |

| Power | AC110-220V, 50-60Hz, USB2.0, 350W |

| Operation environments | Temperature 20-30℃, Humidity 45%-65% |

| Machine size | 940*500*580mm |

| Packing size | 960*510*540mm |

| Gross weight | 50kg |

Powder shake machine:

| Max media | 30cm width |

| Heating size | 40cm |

| Voltage | 220V/5A |

| Power | 3.4kw |

| Media transmission | New belt type |

| Take up function | Automatic inductive |

| Machine size | 850*650*600mm |

| Packing size/Weight | 950*700*700mm/45kg |