Three processes of T-shirt production

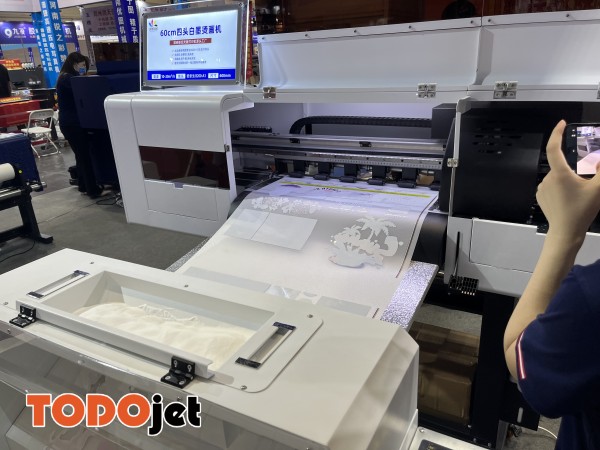

Three processes of T-shirt production.(Weak solvent hot painting, digital direct spray printing, hot transfer printing hot painting). We have A1 and A3 DTF Printer. Our DTF printer can print on any fabrics directly, for example cotton, nylon, polyester, silk, denim, canvas, blends, which is suitable for different business demands. Furthermore, our DTF Printer has high quality, with good after-sales service. Welcome to know TODOjet DTF Printer!

Three processes of T-shirt production:

1.Weak solvent hot painting

The early process is to use the printer to print the pattern on the special transfer paper, and then cut with the edge cutting machine, and then manually hollow out, and finally through the ironing machine on the hot stamping of the fabric.In the later stage, the company developed the spray and engraving equipment, which to some extent liberated the labor force and improved the work efficiency.

2.Digital direct injection printing

Digital direct spray printing, is to directly print the paint ink on the fabric, and then add temperature and solid color, to achieve the printing effect of what you see is what you get.

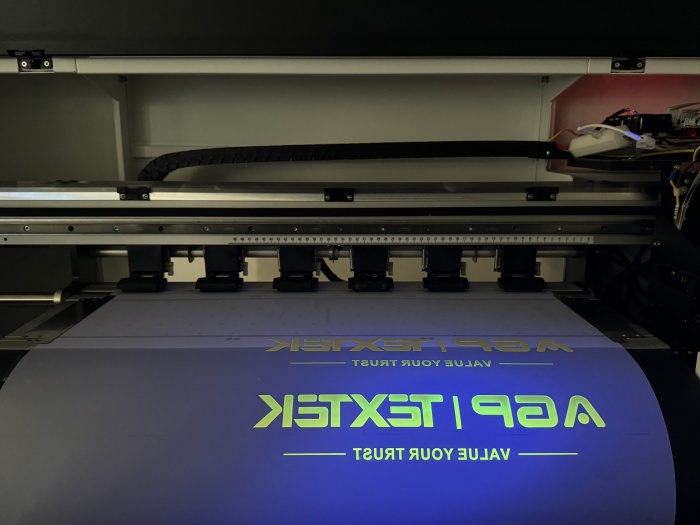

3.Hot transfer printing hot painting

The working principle is to print the paint ink (including white ink) directly on the PET film, and then sprinkle the hot melt powder on the PET film, and finally high temperature solid color.

For example