2021 New technology 3050 Uv Flatbed A3 Size T Shirt Transfer Pet Film label Printer made in China

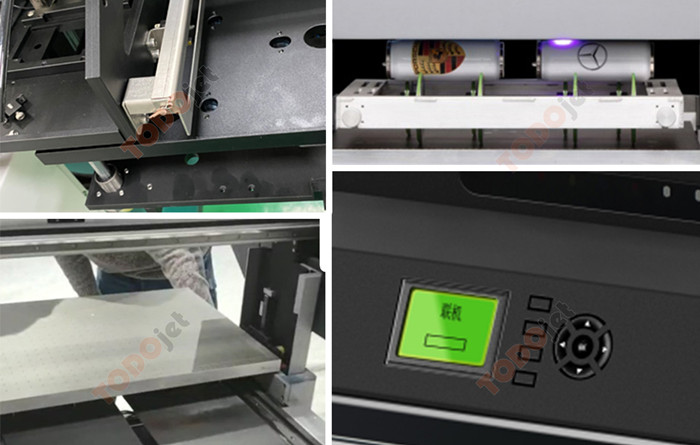

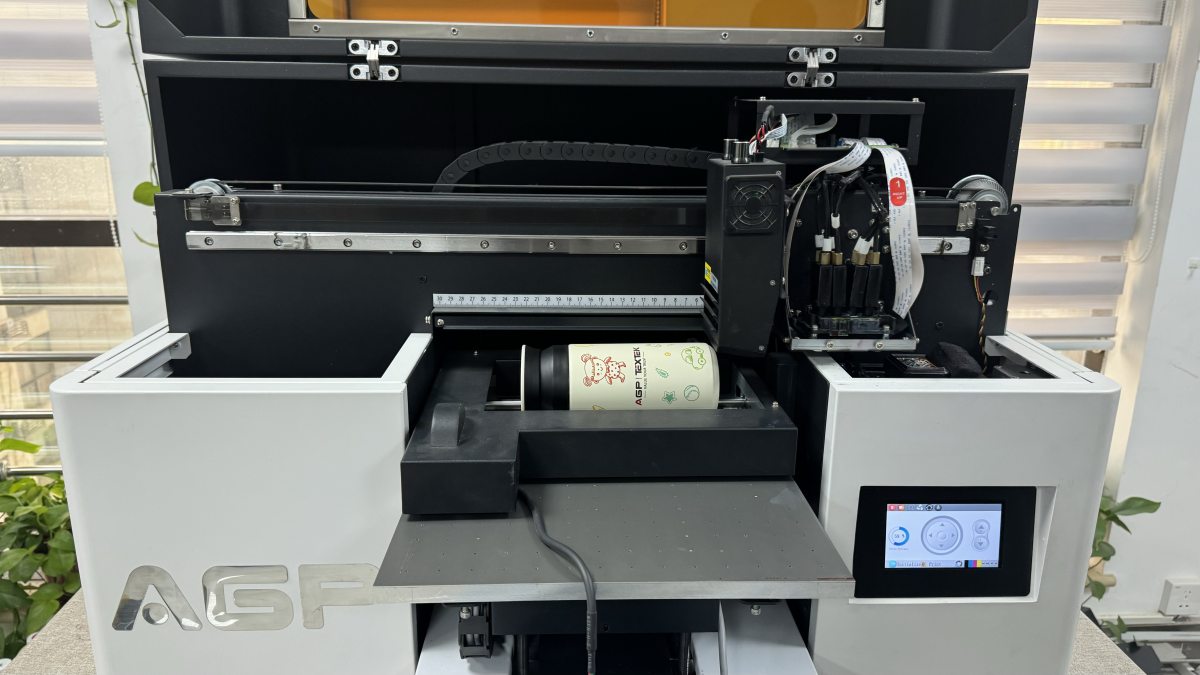

Two Epson printheads support CMYK+W+V

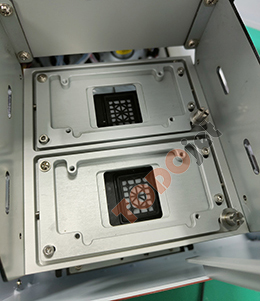

User-friendly control panel, durable suction table

Continuous white ink circulation even if machine turn off

Auto cleaning system

Auto height detecting

Max print height is 15cm

Support bottles&mugs printing

How to solve the UV flatbed printer XYZ axis cannot be reset?

The uv flat printer XYZ axis cannot be reset will directly cause the machine to fail to print normally. It needs to be distinguished that the fault of the XY axis is connected, but the reason for the Z axis cannot be reset is different from the XY axis. The X axis refers to the abscissa direction of the device, the Y axis refers to the vertical coordinate direction of the device, and the Z axis refers to the height direction of the device.

1.The XY axis of UV flatbed printer cannot be reset

- The limit is exceeded, the solution can be pushed back to the carriageof the device;

- The emergency stop switch is not turned on. The solution is to turn on the emergency stop switch.

- Single driver is powered off, the solution is to power on again, if it is damaged, replace it with a new single driver;

- The driver and power supply are damaged. The solution is to replace the new driver and power supply.

- The communication is abnormal and the optical fiber is damaged. The solution is to replace the new optical fiber cable.

- The relay is damaged and has poor contact. The solution is to replace the new relay. If the contact is poor, tighten and reinforce it.

2.The Z axis of UV flatbed printer cannot be reset

- Overrun or stuck, just push the z-axis back to the limited range;

- The communication is abnormal and the optical fiber is damaged.The solution is to replace the new optical fiber cable.

- The screw joint of the motor is loose. Click the screw joint to re-tighten the solution.

- The motor driver has poor contact. The solution is to tighten the lower part of the motor driver.

- The signal cable of the driver is loose. The solution is to tighten the signal cable interface of the driver.