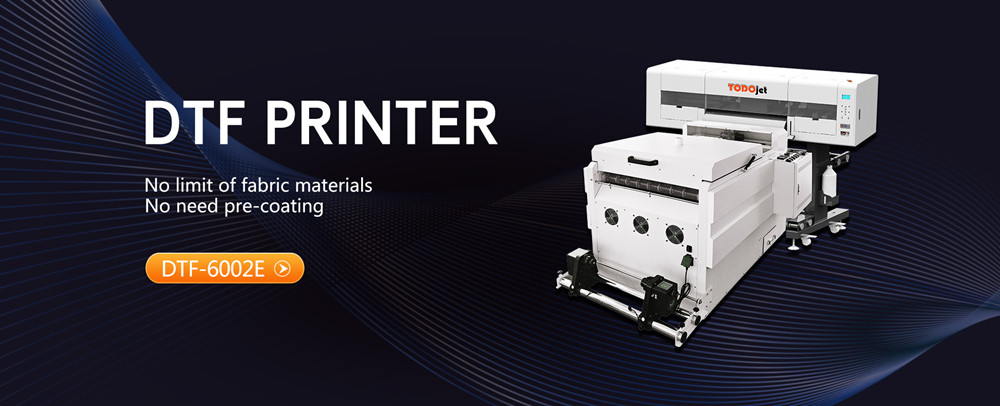

The Newest DTF Printer Shaking Powder Impresora DTF A3 A4 Roll Pet Film With Automatic Dft Shaker

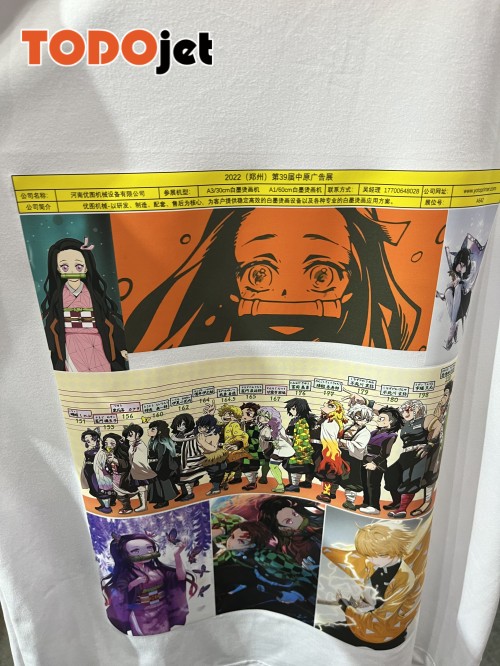

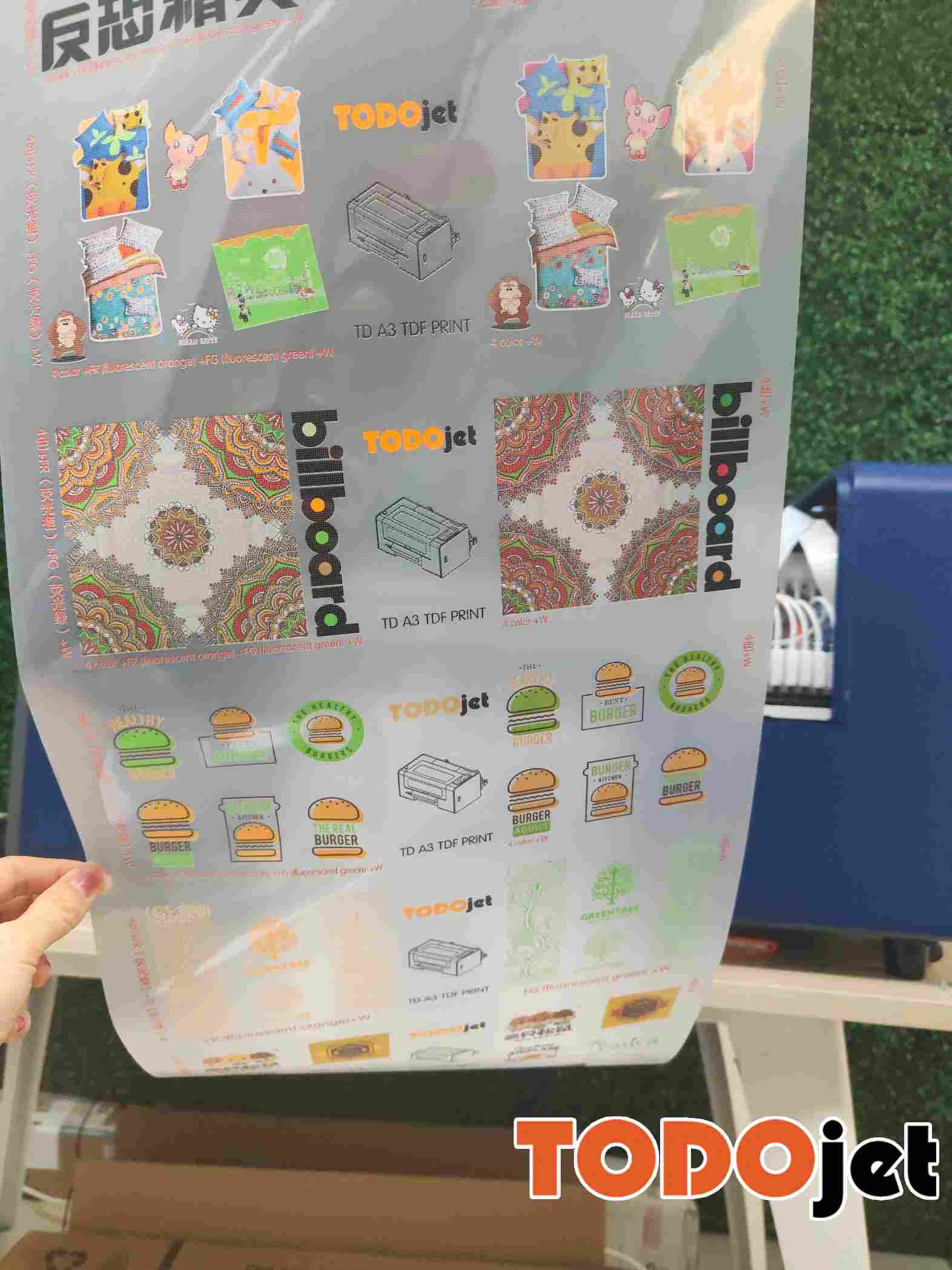

TODOjet the new offset heat transfer solution of digital offset heat transfer printer is as clean as coarse powder and fine powder, free of engraving and waste, soft pattern, breathable and skin-friendly, and the printable materials include cotton fabrics, high-elastic fabrics, Nylon fabric, chemical fiber fabric, swimwear, denim, PVC, EVA, etc.

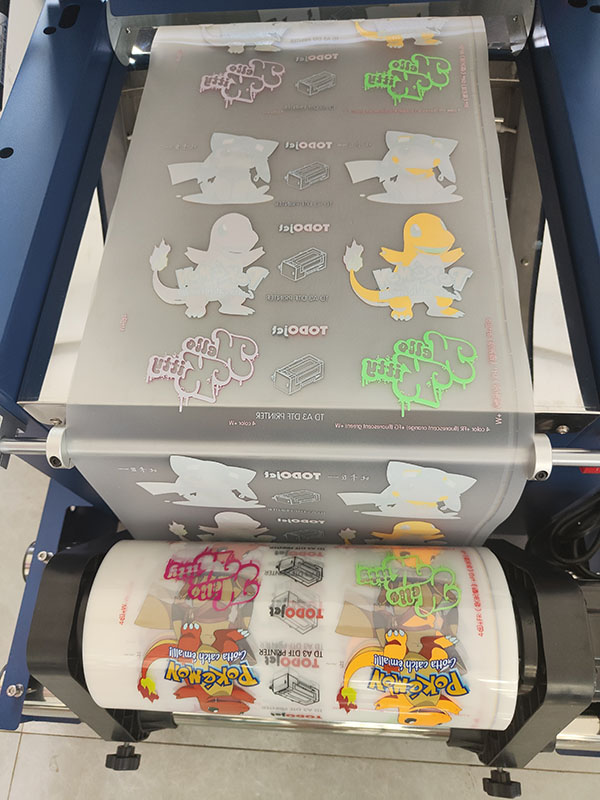

Nowadays, many T-shirt customizations have begun to use digital offset heat transfer technology. Digital offset heat transfer printers are fully hollowed out, and there is no need for cutting plotters, laminating machines, hollowing machines, and no waste discharge. However, many friends may say that the process of this digital offset heat transfer and powder shaking machine is simple, but the effect of shaking coarse powder when shaking powder is relatively good, but it is often not so ideal when shaking fine powder. Yes, it is often not clean. That’s right, this is the case with many digital offset heat press printers on the market today.

In response to the common problem that the shaking fine powder is not clean, the TODOjet digital offset heat transfer printer has set special parameters for shaking fine powder on the powder shaking machine. Through this parameter, the machine shakes the fine powder very cleanly and quickly, and the clothes pattern feels comfortable after heat transfer. , High firmness, strong tensile strength and no cracking.

The TODOjet digital offset heat transfer printer prints and shakes the powder at one time, and it is perfect whether the coarse powder or the fine powder is shaken. The digital offset heat transfer printer can solve the shortage of the previous equipment, and can print in both color and white, without the need for stroke, engraving, waste discharge, and fully automatic production with automatic powdering + tunnel drying system.

TODOjet the new offset heat transfer solution of digital offset heat transfer printer is as clean as coarse powder and fine powder, free of engraving and waste, soft pattern, breathable and skin-friendly, and the printable materials include cotton fabrics, high-elastic fabrics, Nylon fabric, chemical fiber fabric, swimwear, denim, PVC, EVA, etc.