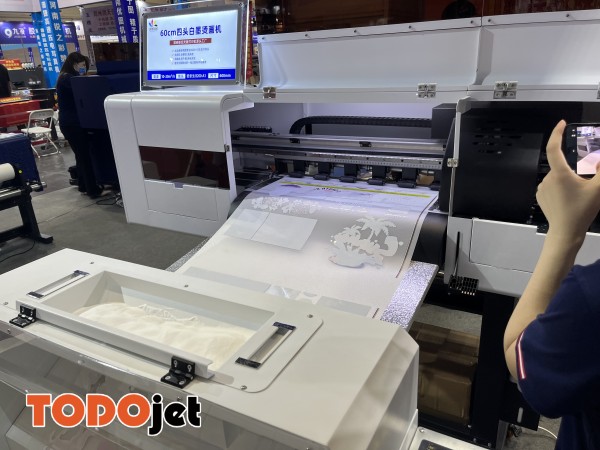

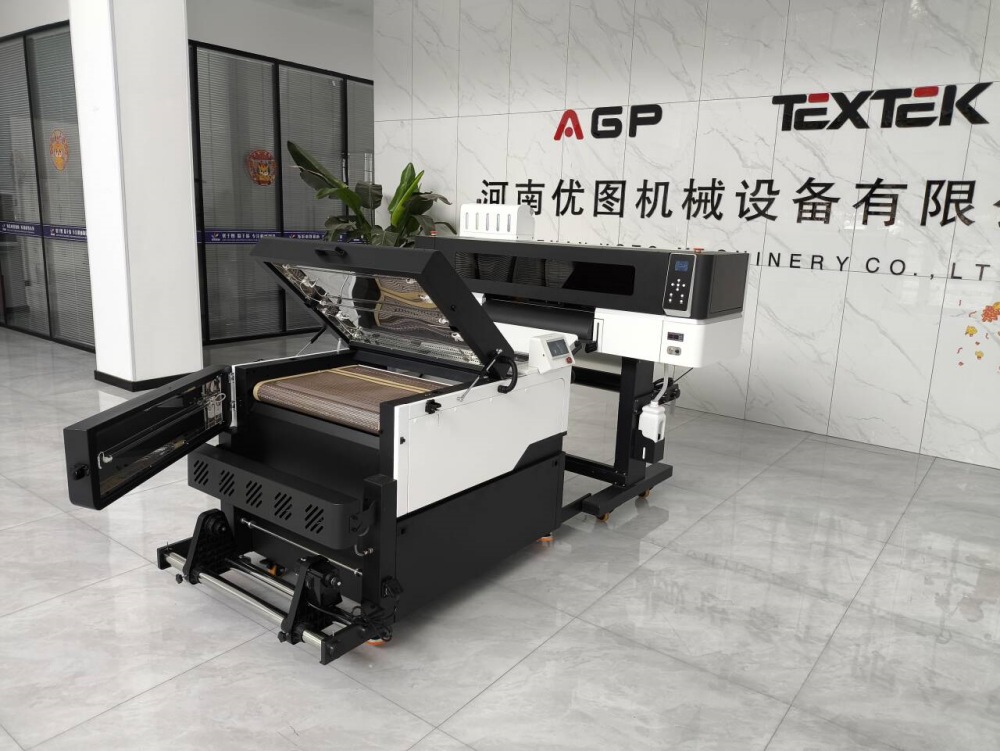

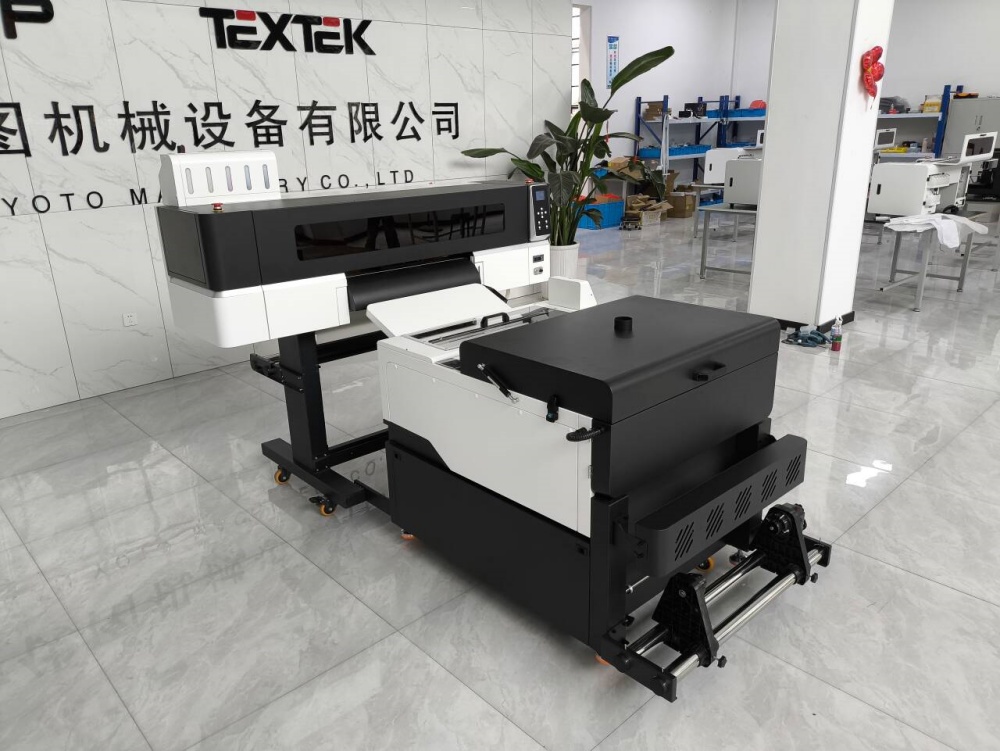

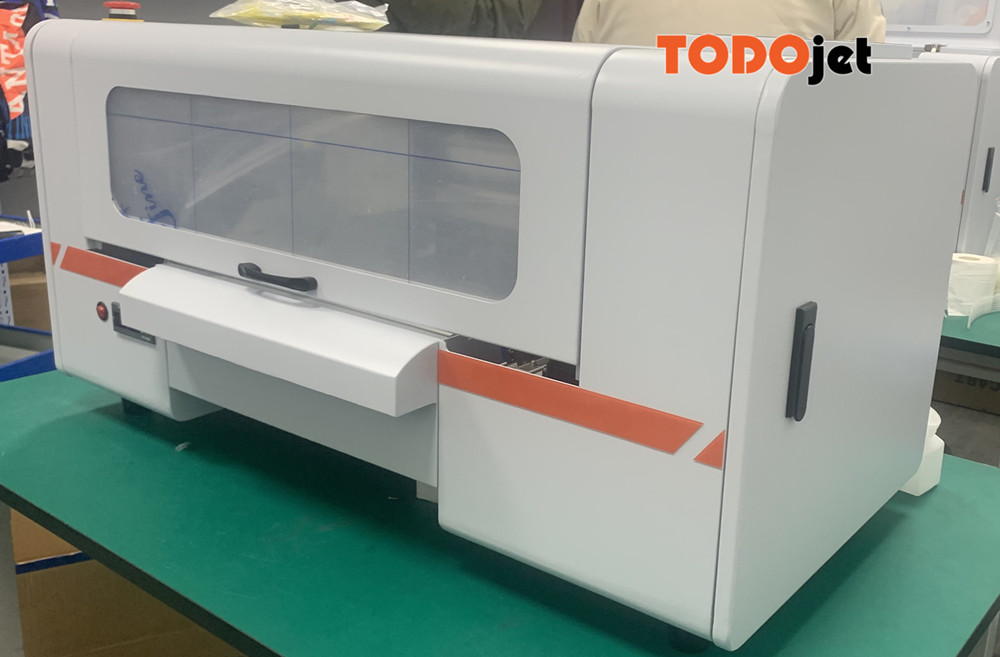

60cm i3200 Dual Heat Transfer Designs Inkjet DTG Printer T-Shirts Printing Machine PET Film Digital Inkjet DTF Printer

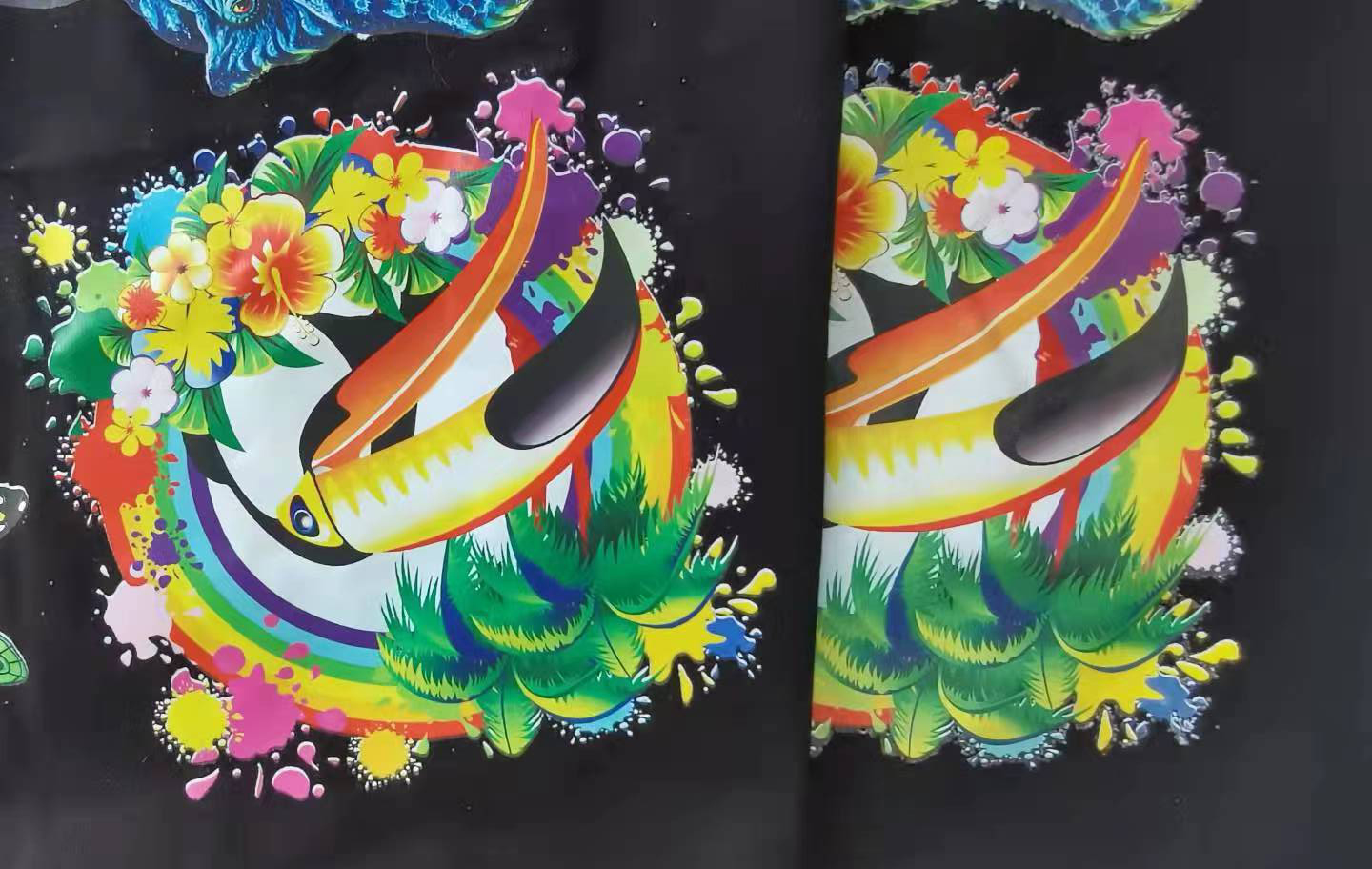

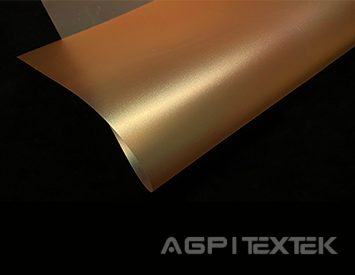

Different from the traditional printing process, white ink heat transfer printing does not require complicated plate-making parts. During the entire printing process, no water is used, and no staff is required to prepare the color paste. After the machine is set up, the ink cartridge is installed. , start the printing mode, the machine will distribute the amount of ink used according to the needs, and directly print the ink on the printing release film and then transfer it to the clothing.

Different from the traditional printing process, white ink heat transfer printing does not require complicated plate-making parts. During the entire printing process, no water is used, and no staff is required to prepare the color paste. After the machine is set up, the ink cartridge is installed. , start the printing mode, the machine will distribute the amount of ink used according to the needs, and directly print the ink on the printing release film and then transfer it to the clothing.

In the whole printing process of white ink heat transfer, the dye produced during the washing process of the printing machine during the mixing process is avoided, so there is no discharge of dye solution and color paste, and no pollutants will appear. Compared with the traditional printing method It is said that white ink heat transfer printing is more environmentally friendly, basically there is no waste discharge, and factories can be built anywhere without affecting the surrounding environment.