Christmas UV Flatbed Printer Maintenance Rules

As Christmas approaches, most users’ UV flatbed printers will face a non-use state for more than 7 days. Coupled with the influence of the cold weather in winter, the maintenance of the equipment will be more thorough and comprehensive than usual. This article mainly discusses how to maintain the nozzle, core components, and external environment.

1. Nozzle maintenance method

(1). Disassembly and maintenance: When the UV flatbed printer nozzle is not used continuously for more than 5 days, the nozzle must be disassembled, and the nozzle must be cleaned with a syringe, cleaning fluid and other tools, and placed on the nozzle with a dampened non-woven fabric. Wrap the hole with plastic wrap, seal it, and place it on an opaque and cool storage cabinet or shelf. When it is reused, it can be cleaned with ink.

(2). Ink pressure maintenance: If you are not going to disassemble the print head, the general civilian type print head, turn on the ink once a day, and print the test strip; for the industrial type print head, turn on the ink once 2-3 days and print the test strip. can. If you find missing needles, wire drawing, etc., you need to clean it as soon as possible.

Note: Since the disassembly and installation of the nozzle requires professional technicians, and the follow-up also involves alignment, if the user does not have such skills, do not operate it privately, otherwise the nozzle will be easily damaged.

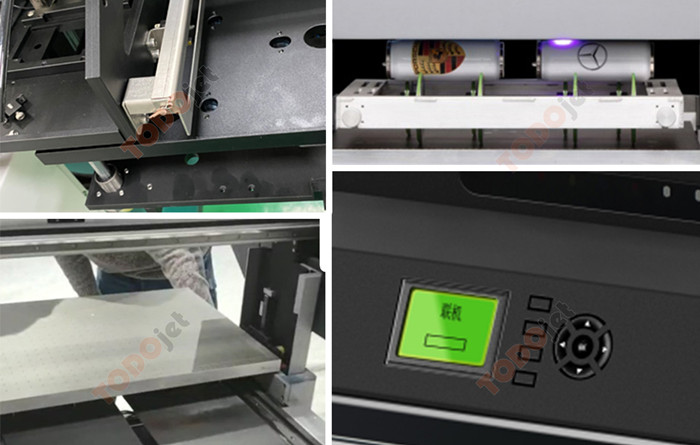

2. Maintenance of core components

(1). The screw and guide rail need to be wiped with lubricating oil;

(2). Appearance sheet metal parts such as platforms, gauges, trolleys, etc. must be kept clean and tidy, and do not place heavy objects on them;

3. The secondary ink cartridges, large ink cartridges, ink tubes, etc. in the ink path can be checked for damage or not, if they are too dirty, they can be cleaned;

4. The interface, circuit, etc. in the board and circuit, check that there is no damage or looseness;

5. After power off, turn off the switch buttons of each part of the machine.

Three, the external environment matters needing attention

(1). If you don’t use it for a long time, you can choose to cover the body of the UV flatbed printer with a whole piece of opaque dust-proof cloth to prevent light, wind and dust;

(2). The operating room of the equipment must be cleaned up, doors and windows must be closed tightly, and no mice will come in and bite the internal wiring of the UV flatbed printer;

(3). If the UV flatbed printer is below zero for a long time, the UV ink in the ink path system needs to be pumped clean or moved to a workshop where the temperature is greater than zero.