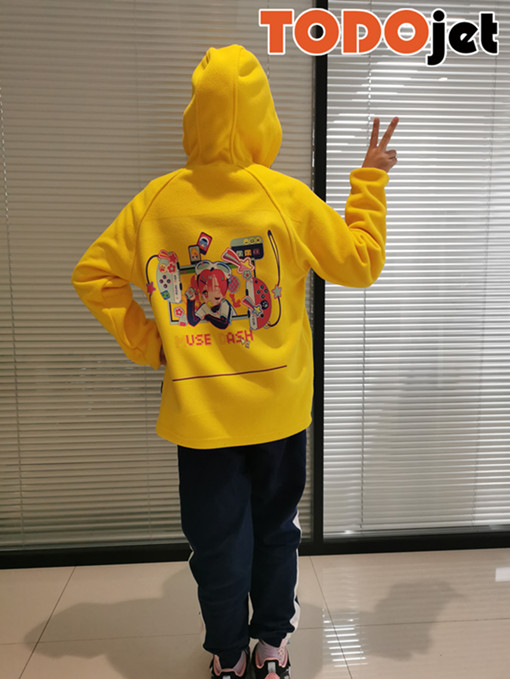

Hot Sell 60cm A1 Dtf Printer Desktop I3200 Printhead Dtf Printer for PET Film T-Shirt Printing

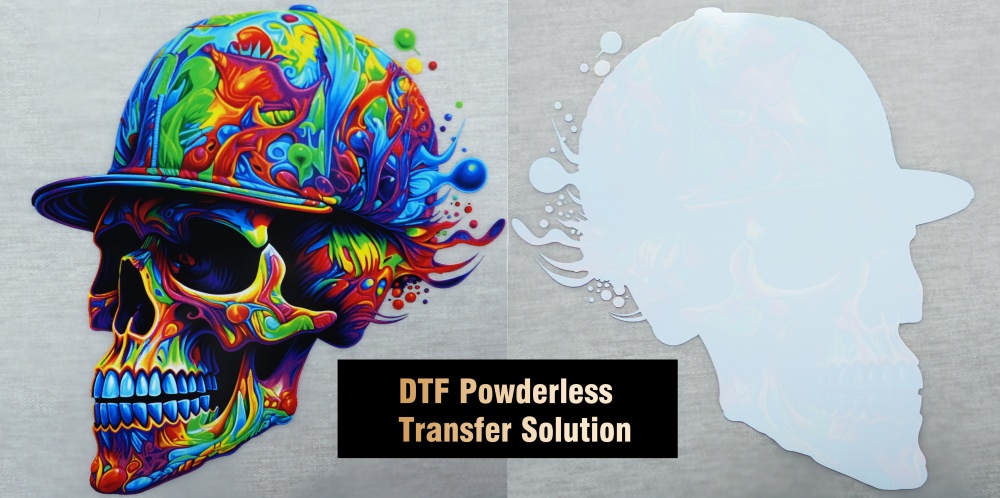

This is a new solution for digital offset heat transfer printer with white ink and color ink. It is suitable for customized small batch printing customers. A variety of fabrics can be printed. It solves the problem that the small letters in the Korean heat transfer process are not easy to be discharged and hollowed out; the production process is mainly that the printer prints the pattern mirror image, the color ink is printed first, and then the white ink is printed; then it needs to sprinkle powder – shake the powder – dry and form. , The printing process requires that the pattern powder should be evenly sprinkled, the edges of the shaking powder pattern should be clean and no hot-melt powder will remain, and the drying temperature should be balanced and the time control should be finer, otherwise the finished pattern product will turn yellow or dry unevenly. The effect of the printed products is not good, so the drying system supporting the Todojet adopts intelligent integrated operation, and the finished pattern printing products are relatively perfect; and the use and operation are simpler, labor-saving, and the cost is also greatly reduced, free of performance integration. Stable, new appearance, high-end atmosphere, more user-friendly design, easy to operate, Chinese and English operating system, Epson I3200 dual-nozzle print output, more realistic drawing and better printing accuracy.

This is a new solution for digital offset heat transfer printer with white ink and color ink. It is suitable for customized small batch printing customers. A variety of fabrics can be printed. It solves the problem that the small letters in the Korean heat transfer process are not easy to be discharged and hollowed out; the production process is mainly that the printer prints the pattern mirror image, the color ink is printed first, and then the white ink is printed; then it needs to sprinkle powder – shake the powder – dry and form. , The printing process requires that the pattern powder should be evenly sprinkled, the edges of the shaking powder pattern should be clean and no hot-melt powder will remain, and the drying temperature should be balanced and the time control should be finer, otherwise the finished pattern product will turn yellow or dry unevenly. The effect of the printed products is not good, so the drying system supporting the Todojet adopts intelligent integrated operation, and the finished pattern printing products are relatively perfect; and the use and operation are simpler, labor-saving, and the cost is also greatly reduced, free of performance integration. Stable, new appearance, high-end atmosphere, more user-friendly design, easy to operate, Chinese and English operating system, Epson I3200 dual-nozzle print output, more realistic drawing and better printing accuracy.

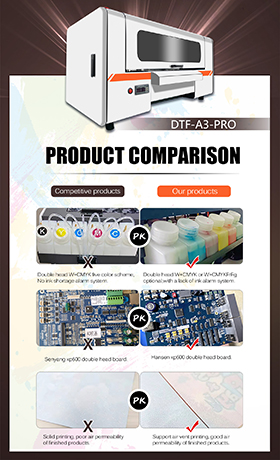

Powder Shaker Machine

| Model | Powder shaker machine TX-60 |

| Print Width | 600mm |

| Media | Hot melt powder and PET film |

| Advantage | Small size,lower shipping cost |

| Auto powder-recycling device | |

| Automatic correction | |

| 3 heating zones | |

| Power Information | 220V 50-60HZ 4000W |

| Package | 920*730*1170mm(0.79CBM)127kg |