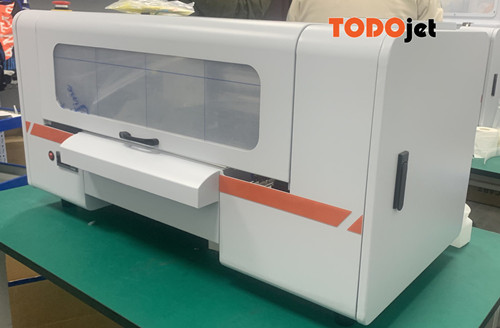

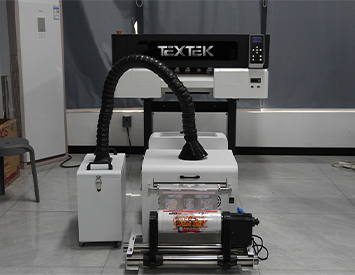

30CM DTF Printer Machine For Epson Double XP600 Print Head A3 DTF Printer T-Shirt Printing Machine

Why do white ink stamping printers skew colors? What are the causes of printer color shift? In fact, the printer supplies are also an important factor in whether the printing color deviation, in the printing supplies performance, if the printer supplies, you can use high quality, good brand reputation of the ink, printing film, hot melt powder. In addition to consumables lead to color cast problems and the following reasons, the following come with me to understand the main five main reasons for the color cast of the hot stamping printer.

Why do white ink stamping printers skew colors? What are the causes of printer color shift? In fact, the printer supplies are also an important factor in whether the printing color deviation, in the printing supplies performance, if the printer supplies, you can use high quality, good brand reputation of the ink, printing film, hot melt powder. In addition to consumables lead to color cast problems and the following reasons, the following come with me to understand the main five main reasons for the color cast of the hot stamping printer.

1, the first step: print the lack of color (can be checked by ink head cleaning), CMYK four base colors can not be missing, while in each base color can not have white or other basic colors appear.

2, the second step: the factors affecting the color of the graphics acquisition, such as the color correction of the scanning software, the CCD photoelectric sensor color conversion capabilities.

3.Step 3: The inevitable color loss caused by color space conversion (such as conversion from RGB to CMYK; conversion from RGB to RGB).

4.Step 4: Do as little color space conversion as possible in the image/graphics processing software (always use RGB color way to open/process/output graphics).

5.Step 5: The color space that the white ink stamping printer can depict is in accordance with sRGB, and the sRGB ICC PROFILE (i.e. *.ICM file) that comes with the driver should be added in the driver’s color management, note that WINNT’s print driver has no color management function.