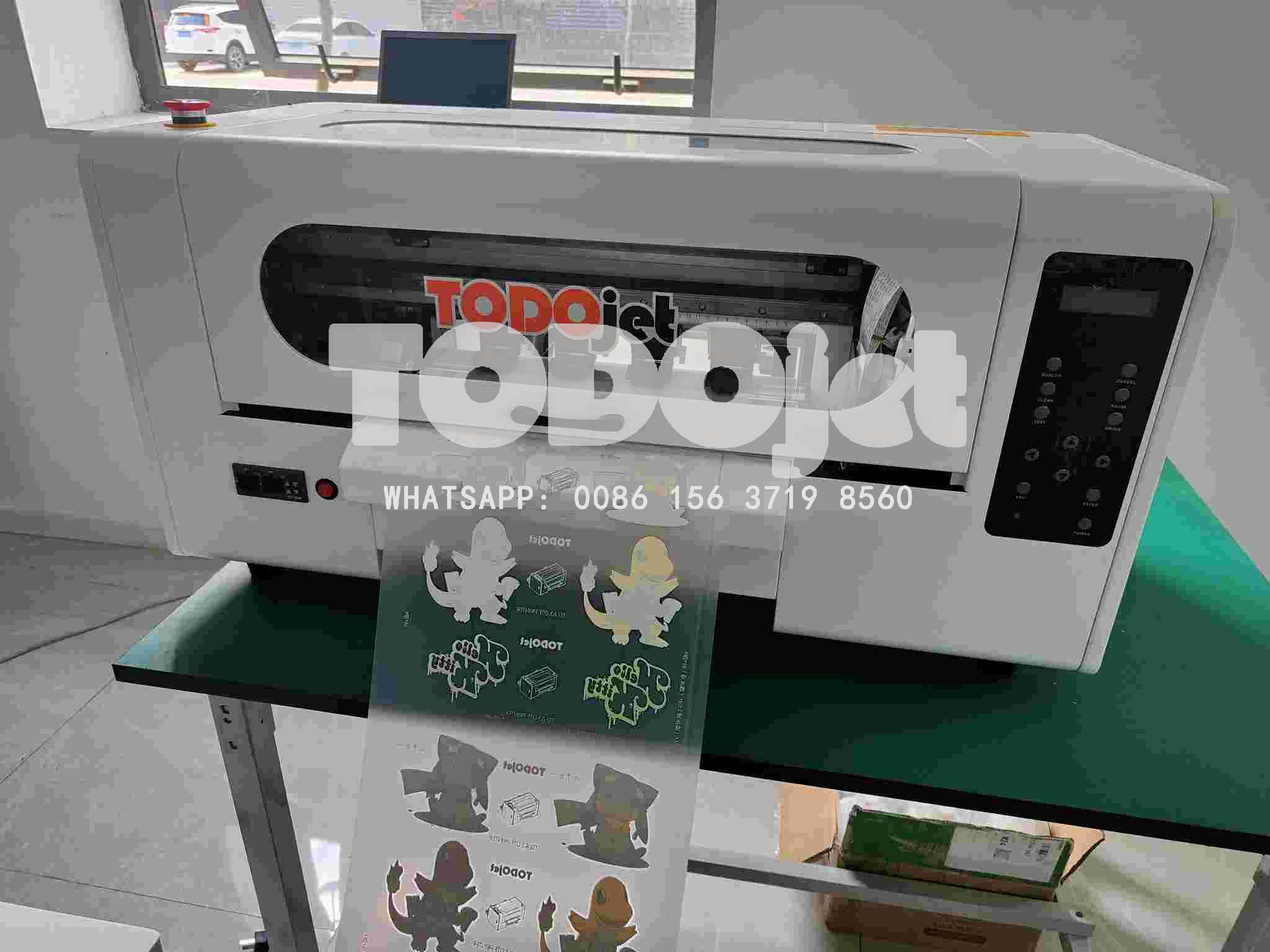

Wholesale A3 DTF Printer Heat Transfer All-in-One for Dark and Light Color T-shirts

Heat transfer technology has a wide range of applications and diverse processes, and its effects are constantly being updated. Heat transfer is also known as hot stamping, transfer printing, etc. Below is a detailed description of the process of rimless Heat transfer (white ink Heat transfer).

Heat transfer technology has a wide range of applications and diverse processes, and its effects are constantly being updated. Heat transfer is also known as hot stamping, transfer printing, etc. Below is a detailed description of the process of rimless Heat transfer (white ink Heat transfer).

Heat transfer printing process in detail:

Image preparation: Create a transparent base file based on the image provided by the customer. For example, if the customer sends an image containing a rabbit, only the rabbit needs to be printed. If the resolution of the original image is too low, you can use AI, CDR and other drawing software to draw pen by pen; if the resolution is suitable, you can directly use the magic wand tool of PSD to remove the background. Need to ensure that the transparency is completely transparent, the outline is clear, and there can be no gradient.

Layout: The common printing film width in the market is 60cm; if the printing width is 7cm, 8 sheets can be laid out horizontally. Layout software is often used, such as AI or CDR, but you can also layout directly in PSD. Once the layout is complete, export it as a PNG or PSD file with a transparent background. It is recommended to choose CMYK mode when drawing, but PNG files only support RGB mode, so it is recommended to use AI to save the PSD file directly in CMYK format.

To add a white ink channel: Open the layout’s transparent background file, hold down the Ctrl key and click on the thumbnails of the shapes in the Layers panel to select all the shapes. Then choose “Modify” in the menu, click “Extend” and fill in 1 or 2 to extend the selection. Then select New Spot Color in the upper left corner of the Channels panel and save it as a TIF file with a spot color (white ink) channel.

Print File Adjustment: Use Mengtai to open the TIF file, adjust the print parameters and output the print file. Since this varies from manufacturer to manufacturer, we will not go into too much detail here.

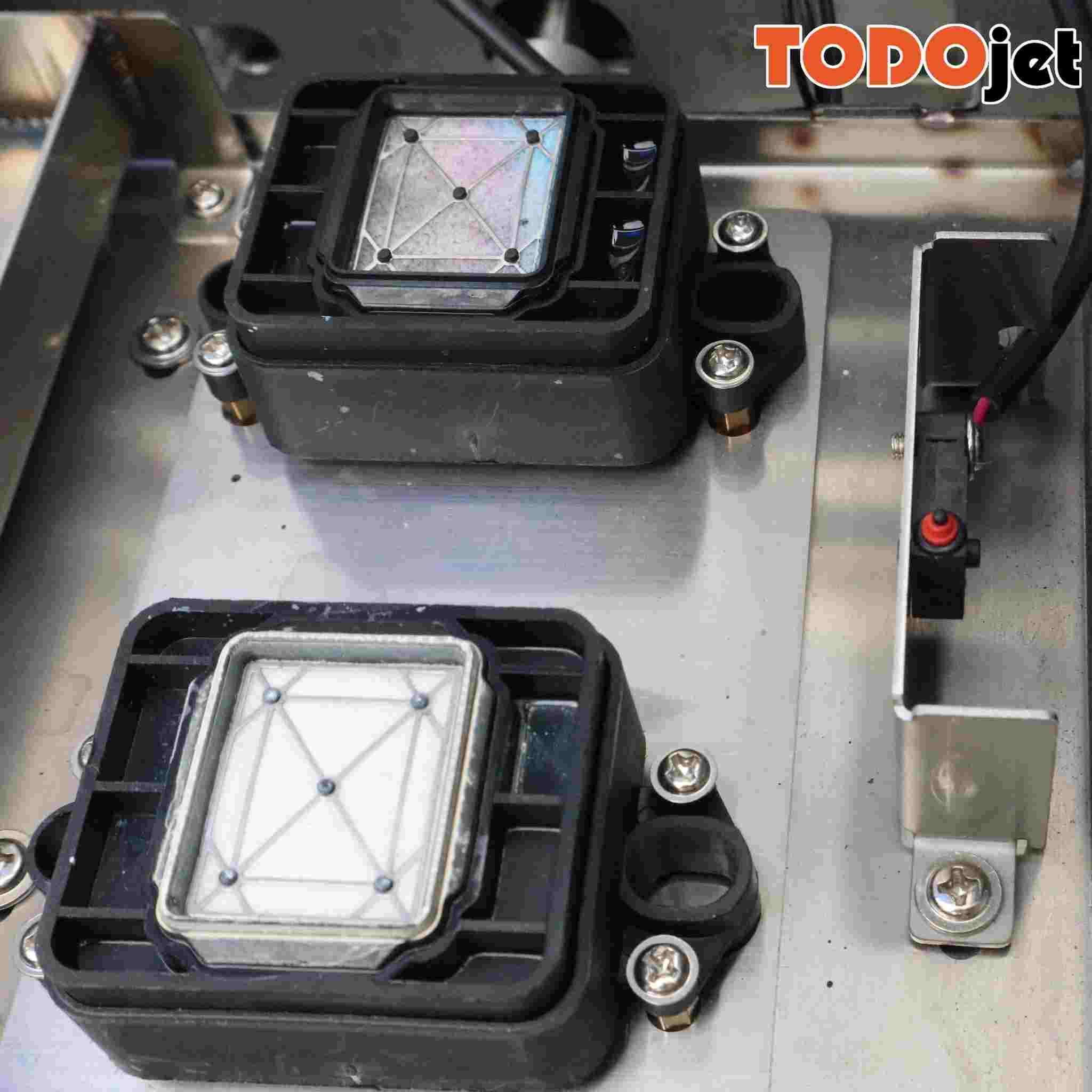

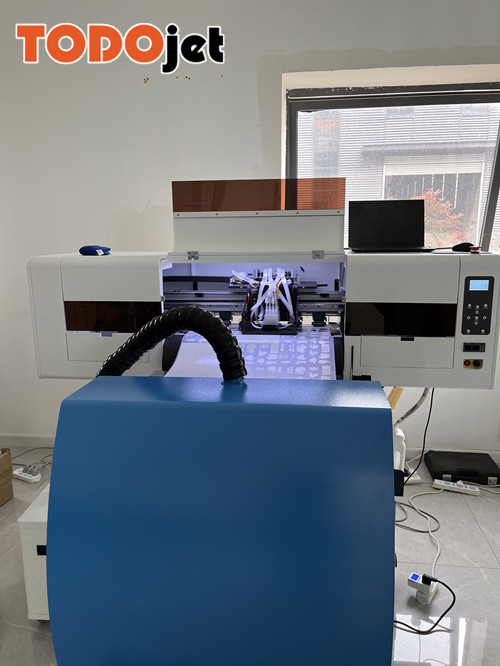

Printing process: Print the image using the appropriate printing software. The printer should be equipped with at least two nozzles, one for white ink and one for color ink. Some printers are equipped with four nozzles, two for white ink and two for color ink. To print, the printer first prints a color pattern on a specific release print film and then prints a layer of white ink on top of it.

![]()

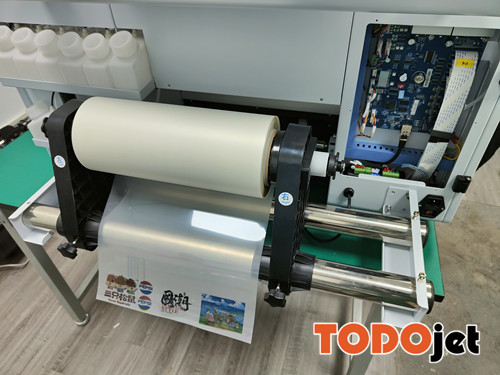

Spreading of hot melt powder: A layer of hot melt powder is spread over the white ink to ensure that the powder adheres to the white ink and that the blank areas are cleaned up, with a shaking motion of the machine, which is why it is called “shaking the powder for Heat transfer”. Finally, the powder is dried in an oven at approximately 110 degrees.

Heat Transfer: A heat transfer machine is used to transfer an image onto clothing or other products.

This comprehensive Heat transfer process helps you achieve higher quality prints, improve productivity and meet market demands!