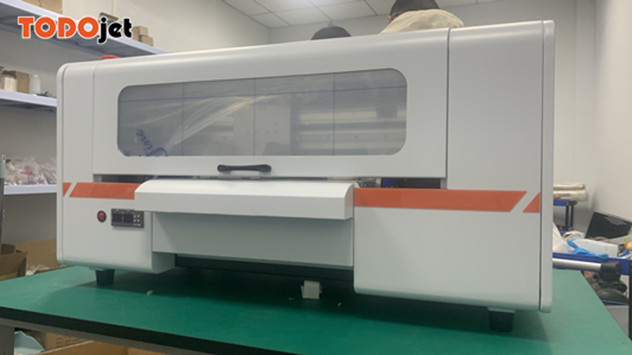

60cm Double I3200 print Head Digital Inkjet DTF Printers With Powder Shake For T-shirt

1. Adjust the appropriate temperature and time:

The temperature range of thermal transfer is about 180-230°C, and the time is about 10-30 seconds. Before the formal batch transfer, a test should be done to determine the process parameters.

2. Adjust the appropriate color density

Adjust the color density in the computer to avoid the situation that the ink is too much and not easy to dry. After adjustment, you need to check the thermal transfer effect.

Product Parameters

| Model | DTF Printer-6502 |

| Print head | 2pcs Epson i3200A1 / 4720 / XP600 |

| Print color | CMYK+W+Fluorescent Color |

| Print ink | Pigment ink |

| Print width | 600mm |

| RIP software | Maintop/Photoprint |

| Printing accuracy | 360*2400dpi, 360*3600dpi, 720*2400dpi |

| Operating environment | 20-28℃ 65-75RH |

| Power supply | 110V/220V 50/60Hz |

| Print speed | 2*I3200-A1:4pass 12sqm/h, 6pass 8sqm/h

4*I3200-A1:4pass 22sqm/h, 6pass 18sqm/h |

| Consumption | CMYK is 15-20ml/sqm, CMYK+W is 25ml/sqm |

| Machine size | 1737*750*1390mm |

| Packing size | 1870*880*720mm |

Kind tips:

1. Adjust the appropriate temperature and time:

The temperature range of thermal transfer is about 180-230°C, and the time is about 10-30 seconds. Before the formal batch transfer, a test should be done to determine the process parameters.

2. Adjust the appropriate color density

Adjust the color density in the computer to avoid the situation that the ink is too much and not easy to dry. After adjustment, you need to check the thermal transfer effect.

3.The hot pressing surface must be close to each other during thermal transfer

During thermal transfer, the hot pressing surface, thermal transfer paper/film, and the surface of the substrate must be close to each other, and there should be no gaps, otherwise the transfer image and text will be blurred.

4.Precautions when using sublimation ink in winter:

In winter, the temperature is low, the viscosity of the ink will increase, and the fluidity will become worse. It is recommended to increase the room temperature to control the fluidity of the ink, so that the ink can reach a normal state. The general room temperature is between 20-28 degrees. If the ink density is reduced, the color will be correspondingly worse.