Home » Products » DTF Printer » Printer Dtf 2022 new technology direct to pet film printer with dtf powder shaker

Printer Dtf 2022 new technology direct to pet film printer with dtf powder shaker

DTF printer is a popular technology in fabric industry. A wide range of applicable materials, such as cotton fabrics, high-elastic fabrics, nylon fabrics, chemical fiber fabrics, swimwear, denim, PVC, EVA etc. It is easy to operate and maintain, suitable to start new business.

Contact US

Get Price

Share:

Content

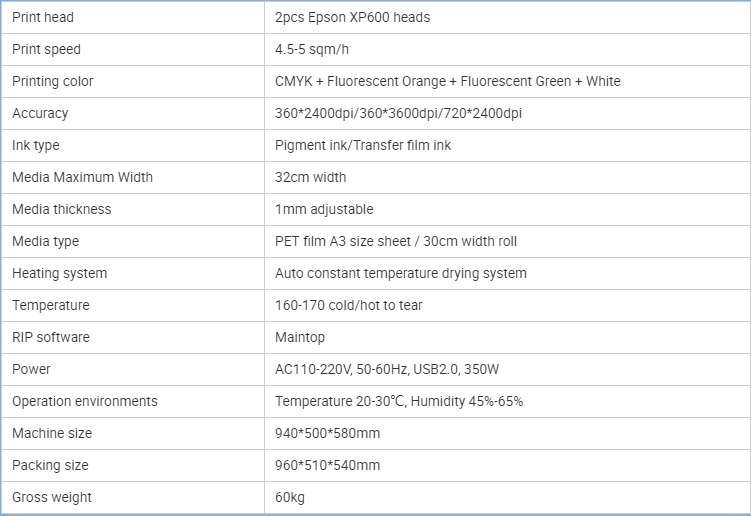

Printer Dtf 2022 new technology direct to pet film printer with dtf powder shaker

We have 30cm, 60cm and 120cm three sizes for preference.

| Model | DTF-6002E | DTF-6004E |

| Print head | 2-i3200A1 | 4-i3200A1 |

| Print speed | 4 pass:12 sqm/h

6 pass:8 sqm/h |

4 pass:22 sqm/h

6 pass:8 sqm/h |

| Print width | 600mm | |

| Machine size | 1737*750*1390mm | |

| Packing size | 1870*880*720mm | |

| Heating system | Pre-heater/rear-heater as standard

Infrared&fan drying system as option |

|

| RIP software | Maintop(standard)/Photoprint(option) | |

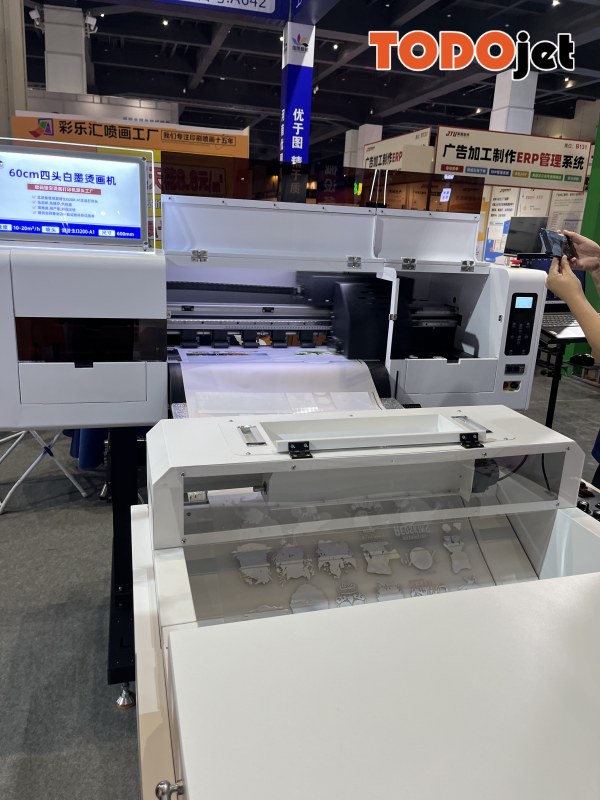

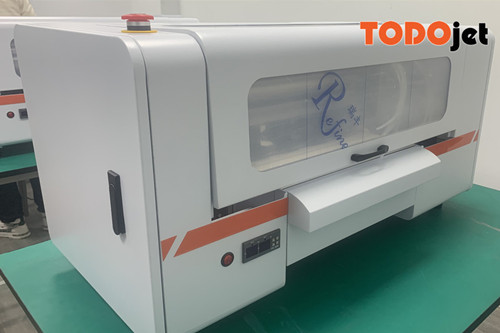

Printer machine

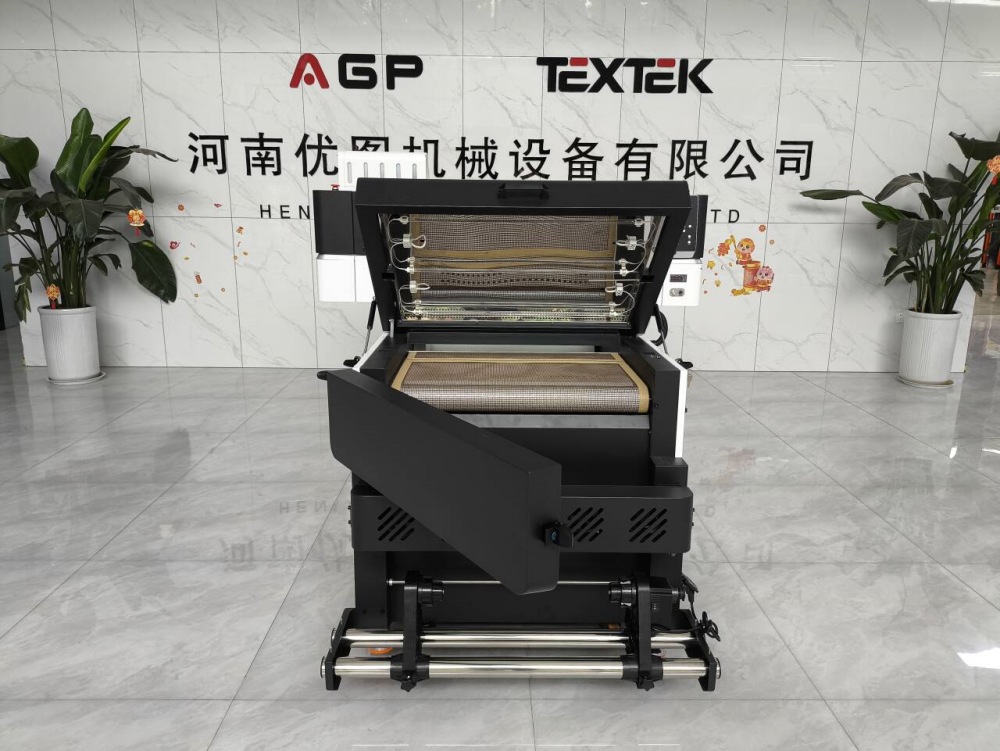

Powder shaking machine

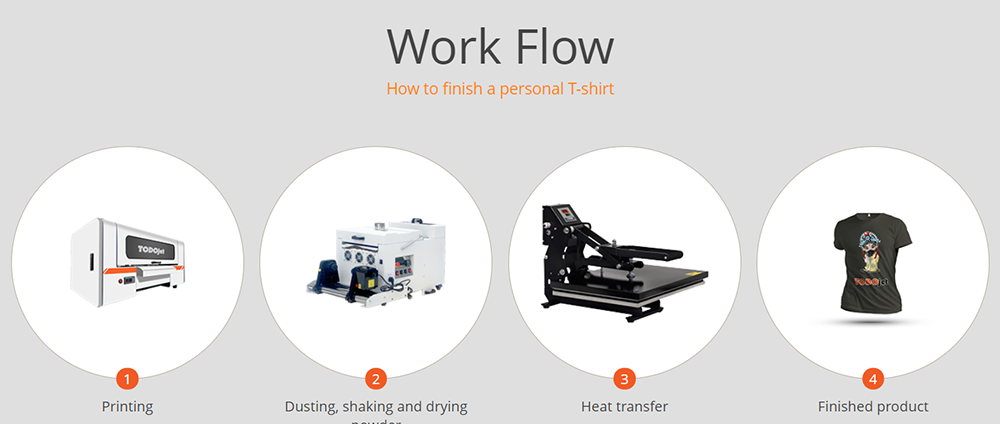

Work Flow

Inquiry

More DTF Printing