2022 High Speed Industrisal DTF Printer 30cm Direct to Film Printer Heat Thermal Transfer

The craftsmanship level of the clothing customization industry shows a trend of continuous evolution and development. The addition of a variety of new custom materials has broken the stereotyped custom style in the industry and created several craft combinations. While on-demand printing is gradually accepted by the public, printing technology has also received more attention.

What is the difference between heat transfer and heat transfer? Do you have a heat transfer T-shirt?

The craftsmanship level of the clothing customization industry shows a trend of continuous evolution and development. The addition of a variety of new custom materials has broken the stereotyped custom style in the industry and created several craft combinations. While on-demand printing is gradually accepted by the public, printing technology has also received more attention.

Among the four major crafts of clothing customization, heat transfer is the most widely used and the most widely used craft. However, in the process introduction of some manufacturers, heat transfer has replaced the position of heat transfer, and some manufacturers directly equate heat transfer with heat transfer. Is the concept of heat transfer and heat transfer the same? What’s the difference between the two?

The relationship between heat transfer and heat transfer

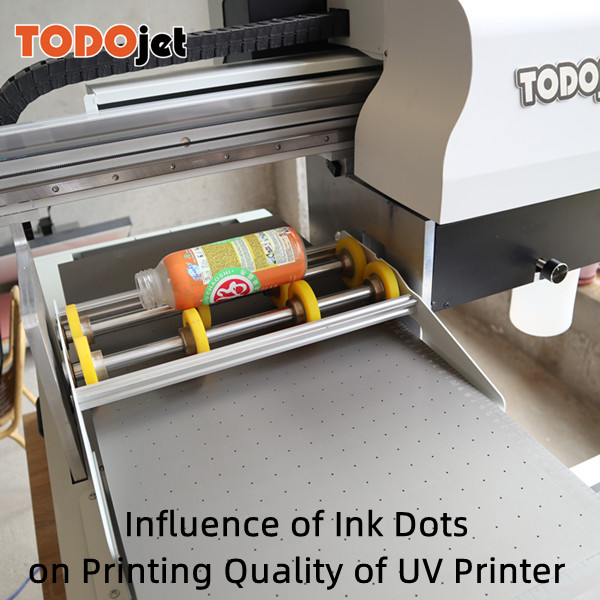

Thermal transfer printing can be divided into thermal sublimation process and hot pressing process. Sublimation refers to the use of dyes with sublimation conditions, which are printed on transfer paper and other transfer carriers by lithographic, screen, gravure and other printing methods (at this time, the pattern is in a mirror-reversed state), and then the carrier is heated by heating. The pattern dye is transferred to the carrier in a gaseous manner.

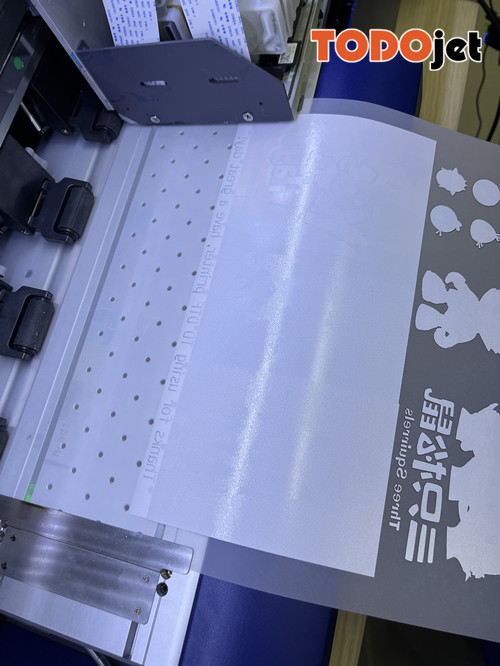

The hot pressing process is the heat transfer technology. The heat transfer production process is generally to print the pattern on the transfer carrier first, and then use the printing equipment to imprint the carrier on the carrier in a high temperature environment.

In short, heat transfer is a sub-category of heat transfer, and heat transfer includes heat transfer.

The scope of application of thermal transfer

Thermal transfer technology was introduced to my country in the 1990s, and has a history of less than 30 years. However, thermal transfer technology is highly respected in the printing industry and is widely used in porcelain, clothing, indicator labels, and hangtags. , aircraft signs, various containers, and water transfer are listed as two major processes in the printing industry.

The scope of use of heat transfer

Heat transfer can produce various effects such as foaming, flocking, reflection, bronzing, laser, etc. It is mainly used in the clothing industry, used on fabrics, leather and other clothing materials to make heat transfer T-shirts, heat transfer sweaters and other clothing.