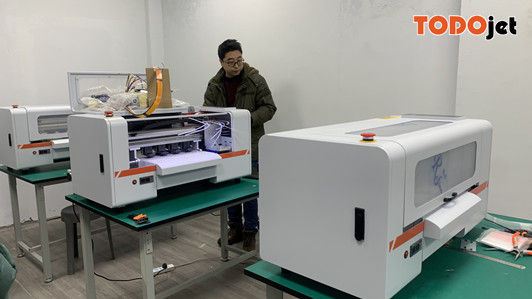

2 xp600 head textile sublimation printer on cotton dtf t-shirt printer printing machine for tshirts with shake powder dryer

1.Powder shaking printing solution is suitable for a variety material such as polyester, pure cotton, and leather,baggage, blends even fabric with silicon oil;

2.Compare to traditional thermal fim solution, powder shaking printing solution no need cutter plotter after printing;

3.Easy processing:printing.powder shaking,drying.heat press,finished;

4.Powder recycling system to avoid waste and save cost;

5.White ink circulation system to avoid clog and ensure stable output quality

6.Excellent printer details which more suitable for powder shaking printing solution, such as anti-static electricitybar and heat fan on carriage

If I have some technical problem, how can you help us to solve it?

Detailed description, photos or video will help our technician analyze the problem and give solution accordingly.

we can also provide door to door service if possible after covid issue end !