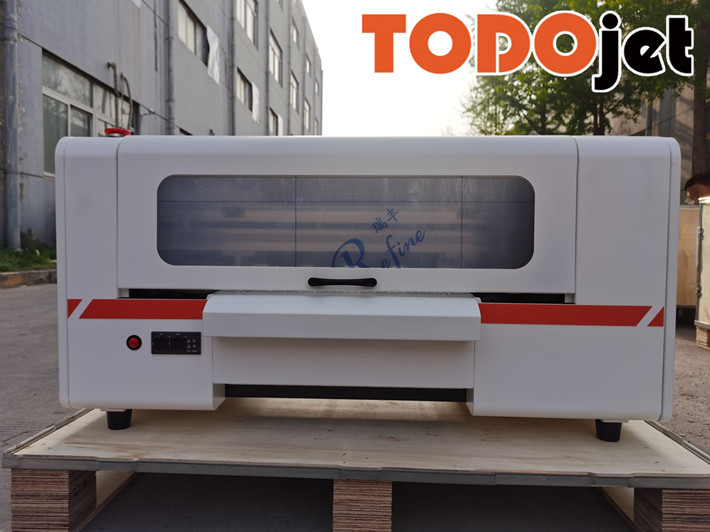

A1: We are the manufacturer of printers and one-stop equipment and accessories providers, with 2000㎡ of workshop and office area.

Q2: How to order?

A2: 1. Please let us know the model and quantity you need. 2. Performa Invoice will be provided for you to confirm.

3. Make the payment after the PI is confirmed by you. 4. The order will be scheduled for production.

Q3: What about the lead time?

A3: Normally 7-15 working days after receipt of payment based on the order volume, the shipping time depends on the means of transportation.