Two printhead heat transfer a3 dtf printer with xp600 and powder shaking machine for T-shirt

Product name:TODOjet A3 DTF Pro Printer

Type:Inkjet Printer

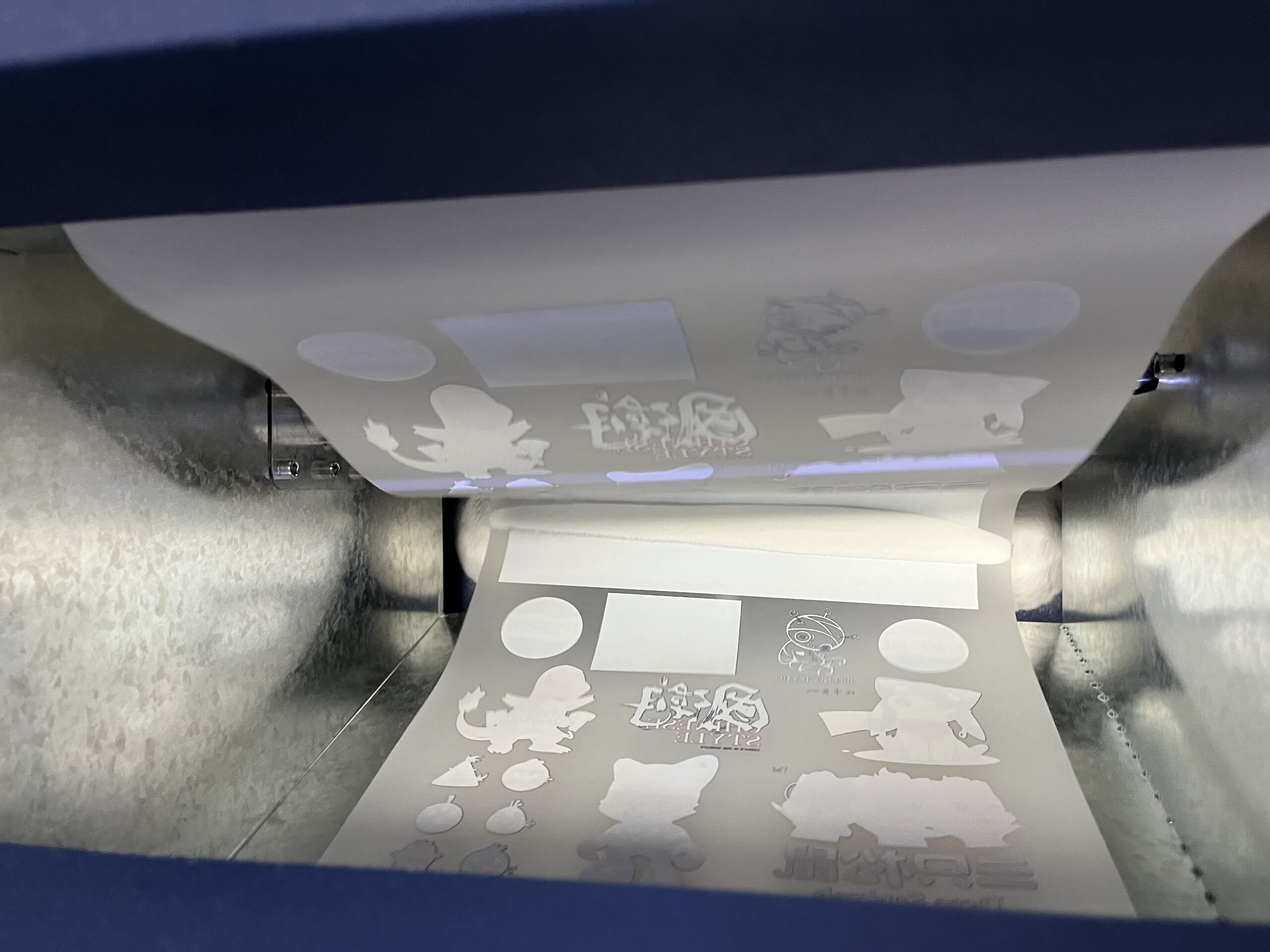

Plate Type:Roll-to-Roll Printer

Applicable Industries:Garment Shops, Manufacturing Plant, Retail, Printing Shops, Advertising Company

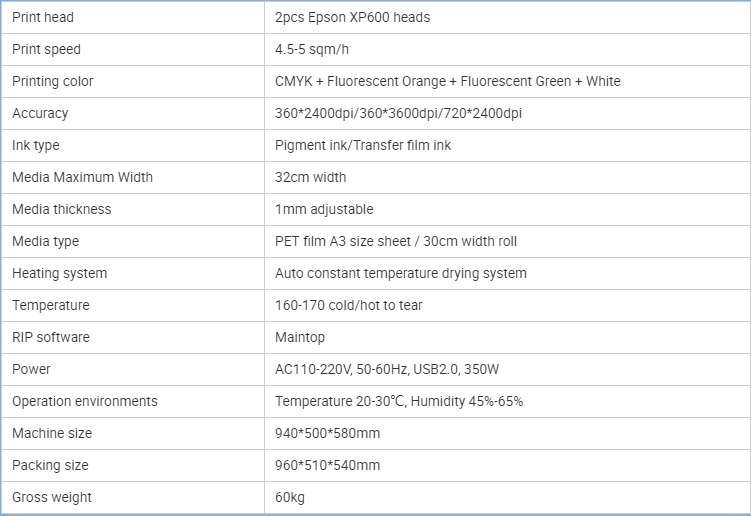

Print speed:4.5-5 sqm/h

Print head:XP600

Automatic Grade:Automatic

Color & Page:Multicolor

Voltage:110V/220V

Dimensions(L*W*H):940*560*500mm

Warranty:1 Year

Print Dimension:300mm, 320mm

Print color:CMYK+Fluorescent Orange + Fluorescent Green + White

RIP software:Maintop/ Photoprint

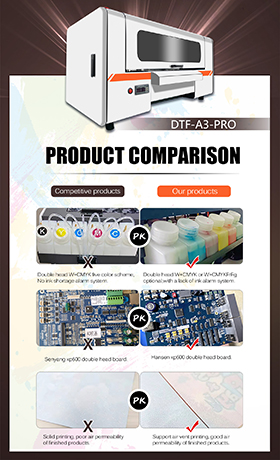

TODOjet A3 DTF Transfer Printer Advantages:

1.The accuracy of the platform is ±2 wires (0.02mm) to ensure the flatness of the platform to the greatest extent.

2. The machine is equipped with an ink shortage alarm, which will alarm when the ink is below a certain level, reminding the user to add ink.

3.There are 2 independent protective sleeves in the ink chain to protect the ink tube and the flat wire respectively. There is a cable protection cover at the opening of the machine to reduce wear and prolong the service life.

4.The front and rear heating of the machine are equipped with 2 independent thermostats, which are easy to control, and are generally set to 40-45 degrees before leaving the factory. The pre-heating is to dry the ink of the film after printing a little, and the post-heating is to simply dry the material before printing to dehumidify and ensure better printing color and pigment adhesion.

5.The machine supports 110V/220V voltage.