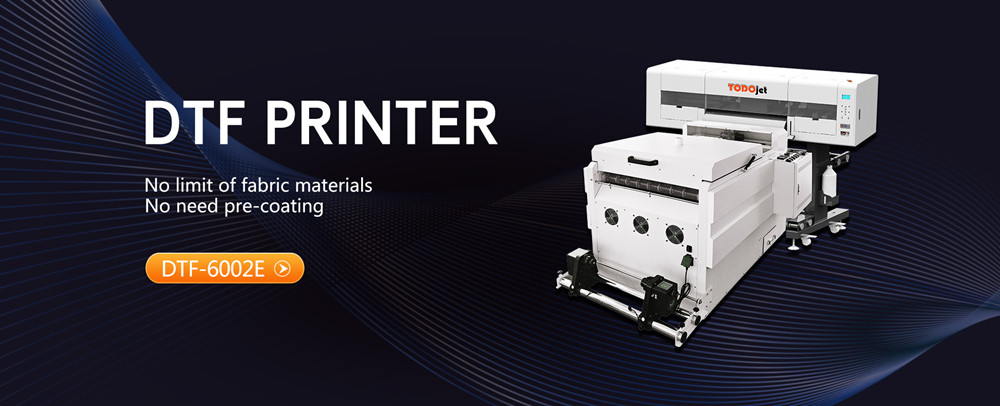

DTF printer usually used together with powder dryer machine,we printing on the PET film first with special pigment ink,and then a powdered glue is applied to the back and then heat cured ready for storage or instant use. Compare to DTG printer, DTF no limit about the non-cotton fabric,and no need pre-treatment, also this way can work out not the mass printing.

This printer can be configured with XP600 printhead or orginal i3200 printhead. Compare to two heads printer, 4 heads with fast speed and you can have more choices about fluorescent color.

FAQ of TODOjet DTF printer?

Q1: How to order the DTF printer?

1. Please let us know the model and quantity you need.

2. Performa Invoice will be provided for you to confirm.

3. Make the payment after the PI is confirmed by you.

4. The order will be scheduled for production.

Q2: What about the lead time of your direct to film printer ?

Normally 7-15 working days after receipt of payment based on the order volume, the shipping time depends on the means of transportation.

Q3: How do you deliver the PET film dtf printer to me?

1. If you have a freight forwarder in China, we can arrange to deliver the goods to your freight forwarder’s warehouse.

2. If you do not have a freight forwarder in China, we can find cost-effective freight forwarders and transportation methods for you to deliver the goods to your country. Such as by sea,by air or by train.

Q4: Is there any warranty for this DTF transfer printer?

Yes, we have a warranty for the printer. We provide 12 months warranty for all the electronic parts including the mainboard, driver board, control board, motor, except the consumables, such as print head, capping, ink pump, ink damper, raster, decoder, print head cables, belt, etc.

Q5: How can I install and start to use the DTF printer?

Normally we provide detailed installation tutorial videos and user manuals. Then we will establish a technical team to provide technical support services, such as online chat and video call, etc. Whenever you have questions about the machines, you can contact our engineer or me directly.