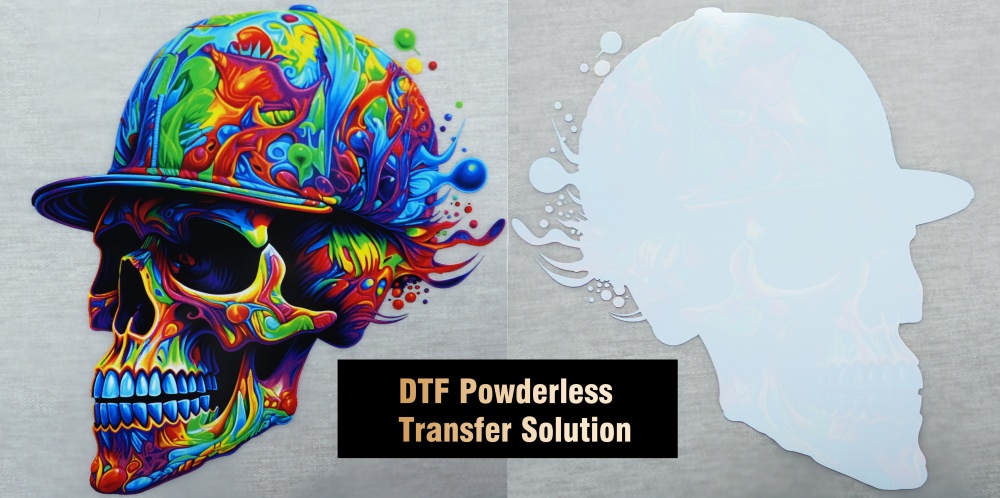

TODOjet PET Transfer Film Printer Pet Film Digital Transfer Printing Machine 30cm A3 DTF Printer for t-shirt

It is recommended to use the TODOjet A3 DTF Pro Printer 6-color fluorescent green fluorescent yellow new solution with fast speed and high quality. After printing, wait for the ink to dry, and then pass the thermal transfer.

1.Proofing production: The transfer factory and the screen printing factory generally do not have offset (offset) machine equipment. Even if this equipment is used for proofing, it is time-consuming and labor-intensive. Because the network of the film is 175 line/inch too thin, the screen is lost and has no layers. It is recommended to entrust a proofing company to help us proofing, so that the cost is low, the speed is fast, and the expected effect can be achieved. There are two types of proofing machines: one is digital proofing, the other is traditional proofing, we choose the latter. When printing the PS version, the film should face up and reverse the picture (opposite to printing), and put it on the release paper we provide (available in the market, in order to reduce the cost, you can prepare it yourself and coat it with a fully automatic or semi-automatic screen printing machine) , At the same time, the proofing company is required to make 1-2 sheets on ordinary 100g-130g copper paper for spare. The printing ink can be used for printing ink. If customers have special requirements, we can provide special ink proofing if necessary.

2.Screen printing: You get the proofing company to make a good sample as scheduled to determine the position of the bite and drying the screen printing. If the customer needs to have the effect of foaming or gold and silver onion glitter, put the white background version (120 mesh mesh) mentioned above. ), PU (160-mesh mesh) version, glue (160-mesh mesh) version together with foam (160-mesh mesh), golden and silver onion (according to the size of the golden and silver onion mesh to determine the mesh number of 40-80 mesh ) The film faces up and the reverse image (opposite to printing) is exposed one by one.

3.Machine Back Adhesive: After getting the proofing, don’t leave 1-2 sheets after printing. First, print PU resin and PU resin on the PU version to make the pattern elastic and washable after printing. Let it dry naturally on a cooling rack. If the customer needs the effect of gold and silver onion glitter, then print the gold and silver onion and let it dry naturally on a cooling rack. White background printing on white background: The ink is best to choose oily elastic white ink with elasticity, strong coverage and washability (you can grind it yourself to reduce costs) After printing 1-2 times, let it dry naturally on a cooling rack. Offset plate, printing glue. Choose the viscosity heat capacity glue suitable for chemical fiber, cotton, acrylic with strong stickiness and strength (you can prepare it yourself to reduce costs). The anti-drying rack is placed in a vertical oven and dried (this process can strengthen the fusion of ink and glue, and also help to volatilize harmful chemical diluents) 60 ℃ for 45 minutes to 60 minutes, and naturally cool out of the box.

4.Transfer printing: Cut 1-2 pieces of the finished transfer paper pattern, put the fabric on the heat press, adjust the pressure of the heat press to 75kg, and adjust the temperature to 150°. The pressing time is adjusted to 15 seconds, and the temperature rises. After it reaches the desired temperature, it is heated and pressed, and the base paper is peeled off while it is still hot, and a beautiful pattern is transferred to the fabric to present you in front of your eyes. After the finished product is released, the finished product is sent to the customer for confirmation, and the whole process is completed.