Sublimation Printing: Exploring the Technique, Machines, and Advantages

In recent years, dye-based sublimation printing technology has rapidly gained popularity due to its superior output quality and wide application across various products. For users engaged in creative customization or garment heat transfer printing, choosing a suitable sublimation printer and understanding the principles of dye sublimation printing is crucial. This article will provide a systematic understanding of the working mechanism of sublimation printing, related technical points, and professional information on sublimation inks, sublimation transfer paper, and advanced dye-sublimation printer equipment in the industry.

In recent years, dye-based sublimation printing technology has rapidly gained popularity due to its superior output quality and wide application across various products. For users engaged in creative customization or garment heat transfer printing, choosing a suitable sublimation printer and understanding the principles of dye sublimation printing is crucial. This article will provide a systematic understanding of the working mechanism of sublimation printing, related technical points, and professional information on sublimation inks, sublimation transfer paper, and advanced dye-sublimation printer equipment in the industry.

What is Sublimation Printing?

Sublimation printing directly transforms sublimation dyes from a solid state to a gaseous state through heating, skipping the liquid stage. The gaseous dyes combine with the substrate material (commonly polyester or polymer-coated surfaces) to form a durable and vibrant pattern. This technology is widely used in products such as T-shirts, mugs, and advertising banners because its clear patterns, vibrant colors, and ability to penetrate deep into fibers are fundamentally different from traditional inkjet printing.

How Does Sublimation Printing Work?

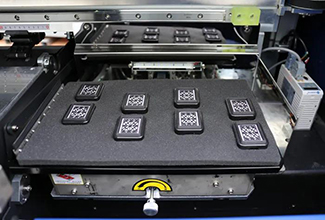

This technology requires specialized sublimation printing equipment and matching sublimation inks. These devices are commonly known as digital dye-sublimation printers. They first print the image onto dye-sublimation transfer paper. Then, a heat transfer machine (commonly a heat press) transfers the image onto the target material under high temperature and pressure. Heating vaporizes the ink and binds it to the material molecules, resulting in a permanent image that is resistant to fading or peeling.

Dye-Sublimation Printer Brands to Consider

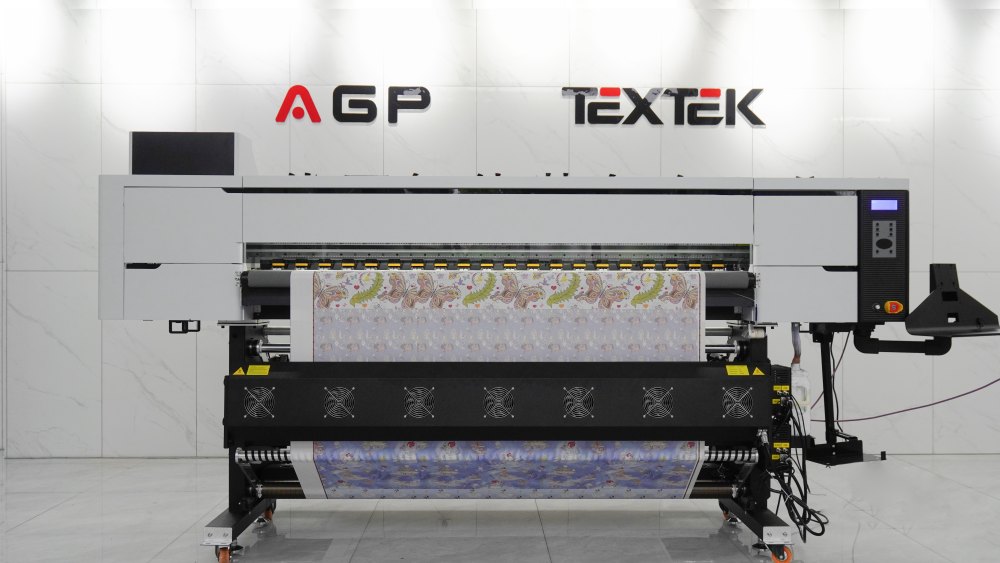

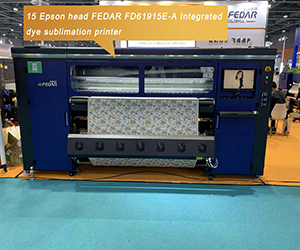

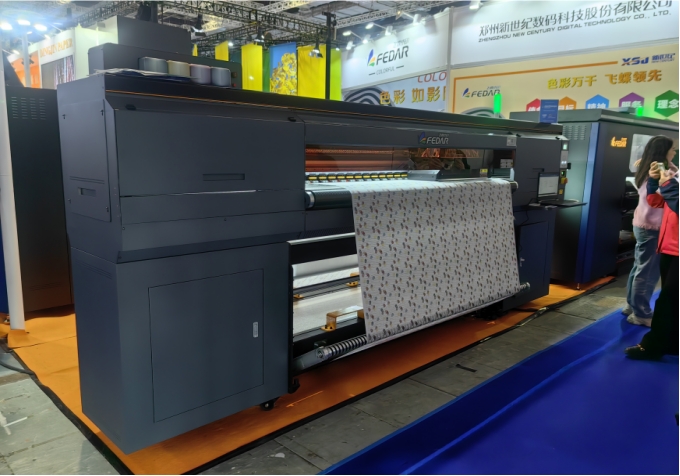

When choosing a dye-sublimation printer, printing speed, image quality, and equipment cost should be considered. Well-known brands in the industry, such as Epson and Fedar, are renowned for their excellent print quality, especially when paired with high-quality dye-sublimation transfer paper and specialized sublimation inks.

For beginners or users handling small-batch production, a modified inkjet printer that uses dye-sublimation ink is an economical option. For high-volume production or those seeking professional printing results, investing in a professional-grade industrial dye-sublimation printer is recommended. Many models from brands like Epson and Fedar excel in image detail and durability and are worth considering.

The Unique Advantages of Sublimation Printing

The core difference in sublimation printing lies in the molecular-level bonding between the ink and the material. Unlike inkjet printing, which only adheres to the surface, sublimation ink penetrates into the fibers or coatings through high-temperature vaporization, resulting in superior abrasion resistance, durability, and color vibrancy. This process significantly outperforms many traditional printing methods in terms of toughness, washability, and color reproduction.

With these advantages, sublimation technology is widely used in customized apparel, promotional gifts, and digital printing. Today, both corporate users and fashion consumers trust the clear image quality, high color saturation, and long-lasting colorfastness of sublimation printing.

Main Applications of Sublimation Printing

To obtain soft, durable, and visually striking customized designs, apparel companies are increasingly adopting sublimation printing. Besides clothing, this technology is also suitable for various materials such as ceramic mugs, metal plates, and advertising flags.

For example, in T-shirt printing, sublimation technology allows the ink to penetrate into the fabric rather than remaining on the surface, making the design less prone to cracking and peeling, resulting in excellent durability. High-quality printing can be achieved on hard surfaces such as metal and wood using thermal transfer, provided a polymer coating is applied.

How to Choose Dye-Sublimation Printing Equipment and Consumables

When choosing a dye-sublimation printer, compatibility with dye-sublimation inks and transfer paper is crucial. Professional users typically recommend using a Fedar-specific dye-sublimation printer to ensure output quality and stability. For small-scale jobs, a modified inkjet printer with dye-sublimation ink can be used. Regarding consumables, Fedar’s original sublimation inks are highly recommended due to their accurate color development and high stability.

Besides the printer, high-quality dye-sublimation transfer paper and sublimation inks are equally important. High-quality ink ensures vibrant and long-lasting colors, while excellent transfer paper enables efficient ink transfer. With appropriate consumables, users can achieve excellent thermal transfer results on various hard and flexible materials.

Dye-Sublimation Printing Operation Process

Once you master the basic tools, getting started with dye-sublimation printing is quite simple. Here are the simplified steps:

-

Creating a Design: Use graphics software to create or select the desired pattern.

-

Printing Output: The design is printed onto sublimation transfer paper using a sublimation printer and corresponding sublimation ink.

-

Material Preparation: Ensure the substrate surface is clean and free of contaminants.

-

Heat Transfer: The printed transfer paper is placed over the material, and the image is transferred using a heat press.

-

Completion and Removal: After cooling, the design is permanently integrated into the material surface, resulting in a vibrant and durable effect.

The Future Prospects of Sublimation Printing

With continuous technological advancements, the sublimation printing industry is constantly evolving. New and efficient printing equipment and consumables are emerging, enabling various businesses to achieve high-quality production using this technology. In recent years, sublimation dyes have seen continuous improvements in color accuracy and durability, indicating a promising future for this technology.

Conclusion

Sublimation printing technology, with its excellent color output capabilities and wide range of applications, has become an important choice in the field of customized printing. Whether producing promotional gifts or professional-grade customized clothing, sublimation technology offers reliable solutions. For creators, with the right equipment and consumables, this technology allows for rich creative expression.

Beginners can start with inkjet printers that support dye-sublimation inks. For professional users and high-volume production, Fedar industrial-grade dye-sublimation printers remain the ideal choice for achieving high-quality, high-durability printing, especially suitable for projects with high requirements for color and detail.