Do you know the difference of DTG and DTF printer in producing products?

The pandemic has led small studios to focus on print-on-demand production, and with it, DTG ink and DTF ink printing have entered the market, increasing the interest of manufacturers who want to start using personalized garments. The DTF market is promising. We cold know more about DTG and DTF Printer.

1.DTG.

✱ It requires pre-treatment: For DTG, the process starts with the pre-treatment of the garment. This step is necessary before printing because we will be working directly on the fabric, which will allow the ink to hold well and avoid transferring it to the fabric. In addition, we need to heat the garment before printing to activate this treatment.

✱ Print directly onto the garment: so the process can be shorter than DTF and you don’t need to transfer.

✱ Use of white ink: We can choose to use a white mask as a substrate to ensure that the ink does not mix with the color of the media, although this is not always necessary (for example on a white substrate) and it is also possible to place white only in certain areas in order to reduce the use of this mask.

✱ Printing on cotton: With this type of printing, we can only print on cotton garments.

✱ Final press: To fix the ink, we must perform the final press at the end of the process, where we will prepare the garment.

The process of DTG:

Step 1: Prepare an artwork or a shirt

Step 2: Spray pretreatment fluid for light or dark shirts

Step 3: Hot pressure

Step 4: Print with a DTG printer

Step 5: Hot pressure

Step 6: Complete

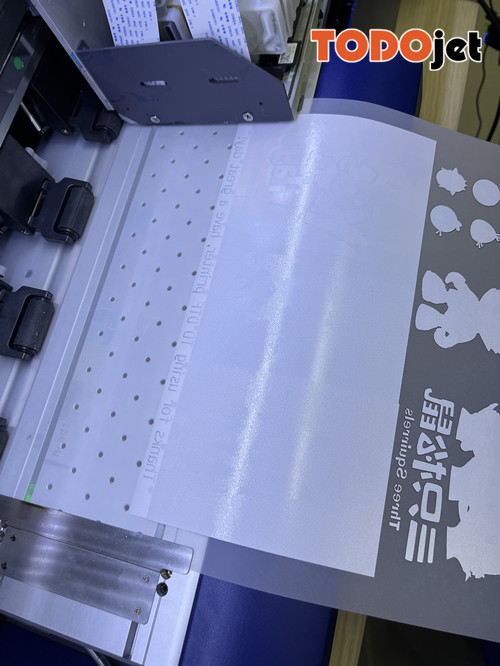

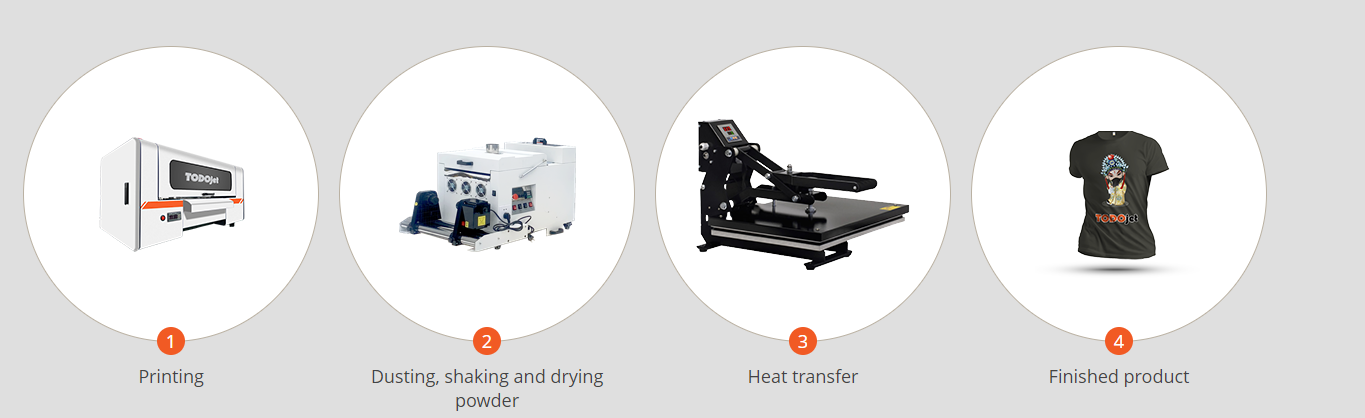

2. The workflow of our A3 DTF Printer:

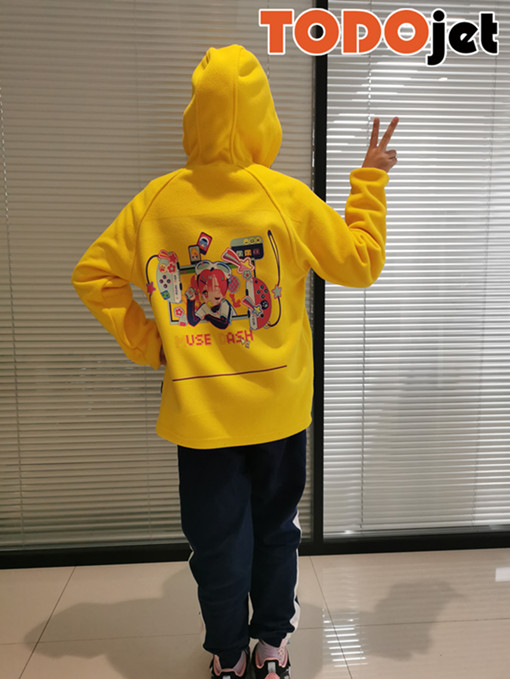

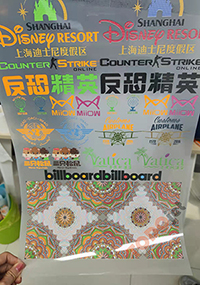

3. The effect od DTF Printer: