Why DTF Printers are the future of local printing industry like our A3 DTF Printer with 2 XP600 Printheads.

Are you a printing business that has recently heard about Direct to Film printers or printer DTF? Yes, digital printing is still a relevant and prevalent printing method, but DTF is definitely taking the market by storm. Since 2020, Direct to Film printers and their PET films have locked horns with the conventional printing techniques. Many believe that DTF printers are going to be the future, so let us find out why DTF is stirring the printing sector. Most DTF printers have a mechanism where thick white ink circulates within the ink tube. That said the white ink circulation mechanism of most DTF Printers with PET films produces the most vibrant and high-quality print designs and images. Just like our A3 DTF Printer with 2 XP600 Printheads.

1. DTF printers are not just a concept or a technology about to roll out.

There are actually manufacturers who are currently offering some of the most efficient and high-quality Printer DTF. Other traditional techniques such as screen printing can only create simple designs and shapes on prints. Plus, the setup process involved in conventional methods takes a lot of your time and resources which can add up the overall production costs.

2. The colors.

The old techniques such as DTG can only support a limited number of colors. The more colors you use, the higher your printing cost will be. So, you will need a substantial amount of investment to get the product into the market before you can see any profits in your bank account.For example, DTG printing will require a substantial monetary investment for large batches of printing. This makes it a high-risk process because you will have to bear all the costs of damage and waste.

Plus DTF printing process is one of the slowest conventional printing methods that will cause delays in processing huge orders.

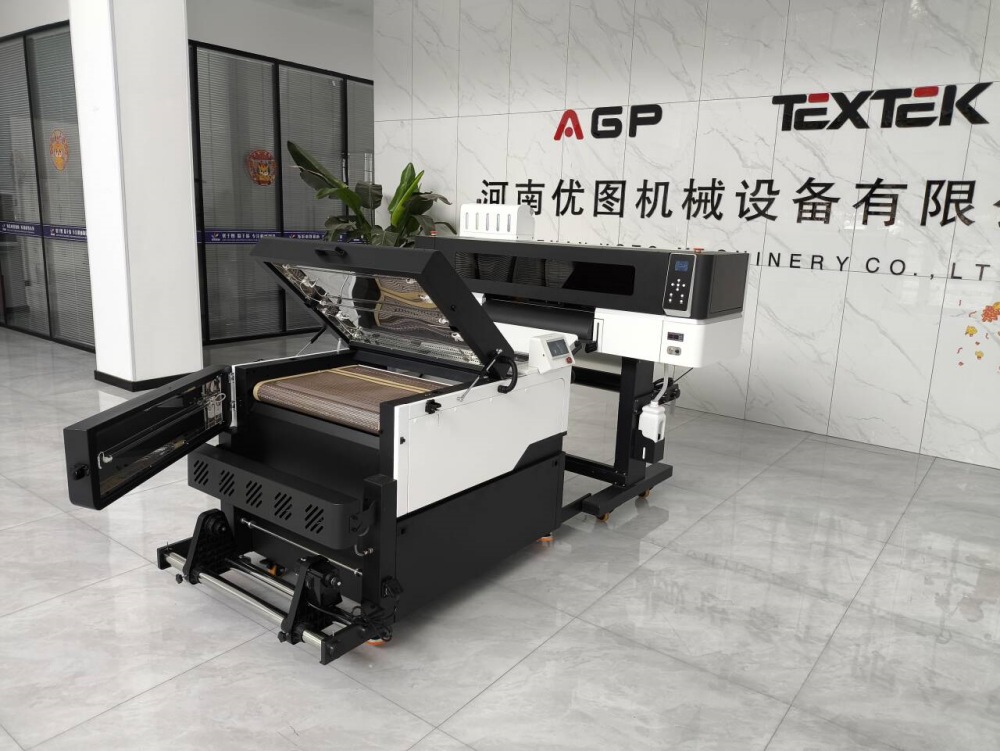

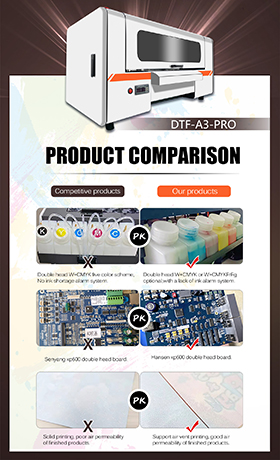

3. DTF Printer-A3

Printhead: 2PCS EPSON F1080

Printing width: 30cm

Printing Speed: 4.5sqm/h (about 15m/h)

Software: Maintop/Photoprint

Ink type: Pigment Ink

4. Advantages

No limit of fabric materials

No need pre-coating

No need plate making

No need contour cutting

Environment-friendly pigment ink

Small invest, large benefit