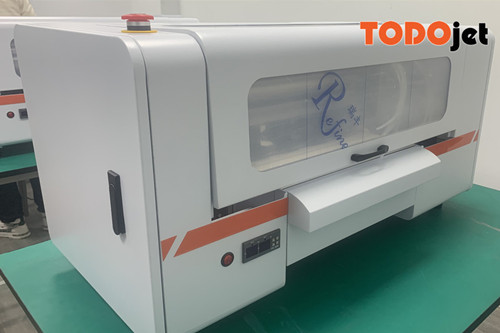

New DIY Digital A3 A4 Inkjet T-shirt Printing Machine Pet film transfer DTF Printer L1800/XP600 printhead

1.Up and down cap station

Better seal performance for the printhead

2.Temperature control

Front and back, 2 stage heating

3.Hiwin guide rail

Printing more stable and quiet

4.Good working performance

Fluorescent orange and green are support

The key to choosing the quality of heat transfer printing machine:

The temperature control and time control of the heat transfer machine seem to be very simple now, but it is difficult to achieve uniform temperature and pressure for machine hot stamping. Whether the pressure of the machine can be uniform depends on the structure and processing technology of the machine. To achieve uniform temperature, the key is the heating plate of the machine. The heating plates of heat press machines all over the world are made of cast aluminum. The more heating tubes, the more uniform the heat will be. In order to cater to customers’ pursuit of low prices, some manufacturers desperately reduce the materials used in the machine, especially the weight and quality of the cast aluminum heating plate, resulting in poor machine quality and high transfer rejection rate, which increases the user’s cost of use. and labor costs.

It is recommended to choose TODOjet A3 DTF Pro Printer offset heat transfer, with fine pattern, exquisite effect, offset photo effect, and can maintain the charm and artistic charm of the original work.

Product Parameters

| Print head | 2pcs Epson XP600 heads |

| Print speed | 3-10sqm/h |

| Accuracy | 360*2400dpi/360*3600dpi/720*2400dpi |

| Ink type | Pigment ink/Transfer film ink |

| Media Maximum Width | 32cm width |

| Media thickness | 1mm adjustable |

| Media type | PET film A3 size sheet / 30cm width roll |

| Heating system | Auto constant temperature drying system |

| Temperature | 160-170 cold/hot to tear |

| RIP software | Maintop |

| Power | AC110-220V, 50-60Hz, USB2.0, 350W |

| Operation environments | Temperature 20-30℃, Humidity 45%-65% |

| Machine size | 940*500*580mm |

| Packing size | 1000*640*64mm |

| Gross weight | 89kg |

TODOjet A3 DTF Pro Printer:

1.You can transfer pictures on any material. Such as: T-shirts, towels, scarves, cotton clothes, etc.

2.Fast printing speed: low input cost, high-speed printing is fully suitable for industrial mass production;

3.Scope of product application: A. All franchise stores, photo studios, wedding photo studios, scenic spots, hospitals, schools, etc.;

Simple and convenient operation: no need for plate making and repeated color registration process, easy to operate and maintain;

4.Overcome the limits of materials: It can print any medium within the specified thickness, completely overcoming the traditional printing method that can only use special paper and special specifications, and can use very thin or very thick objects, and its thickness can reach: 0.01mm- -200mm.