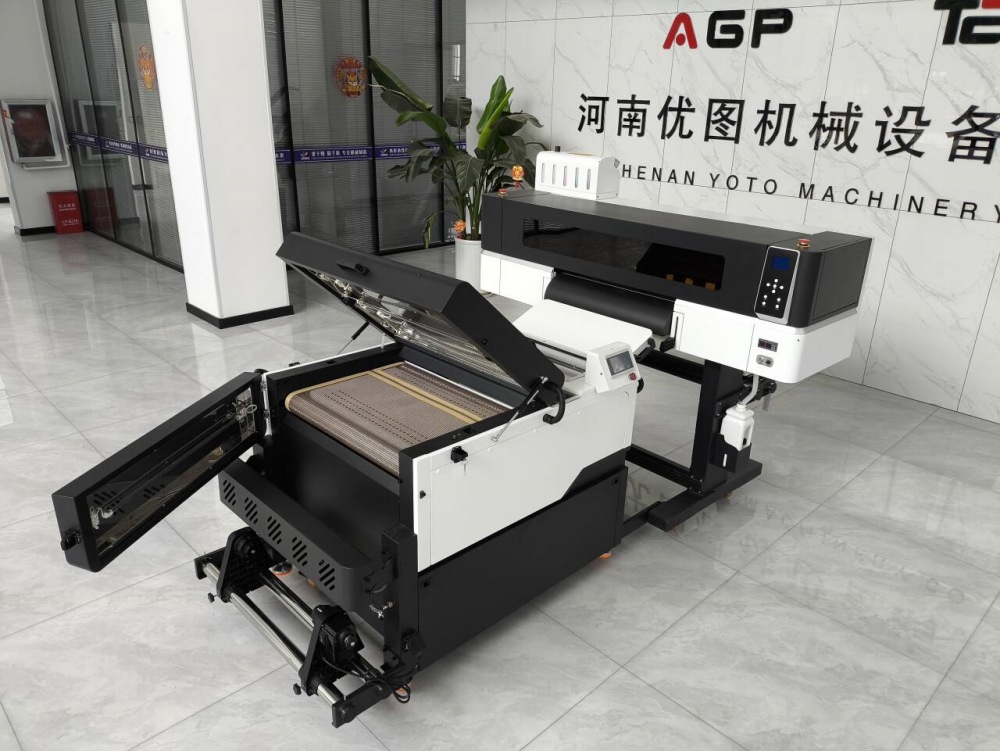

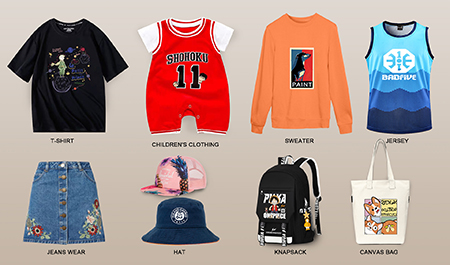

New technology digital offset heat transfer printing scheme, personalized, small footprint, one person to operate multiple machines.

Automatically shake powder to save labor

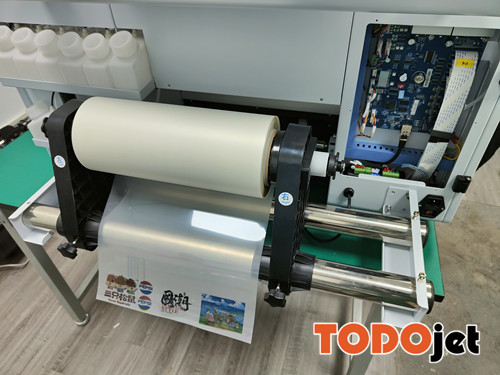

The whole set of equipment is equipped with an all-in-one automatic drying and shaking powder machine to align with the printing pattern, the hot-melt adhesive powder is sprayed evenly, the automatic drying and color fixing, and the synchronous winding, saving time and effort

Steps

Printing and heat transfer is completed at one time, and the operation is simple and fast

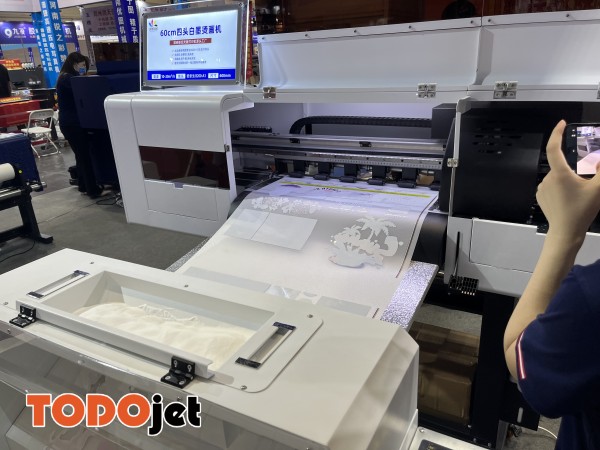

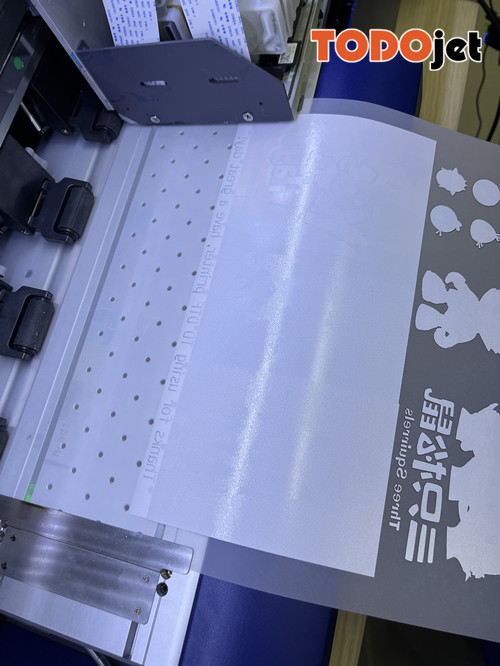

Step 1: Typesetting adjustment parameters to print the pattern on the heat transfer film

Step 2: Go directly to the powder shaker to automatically add powder, shake powder to dry, and roll up

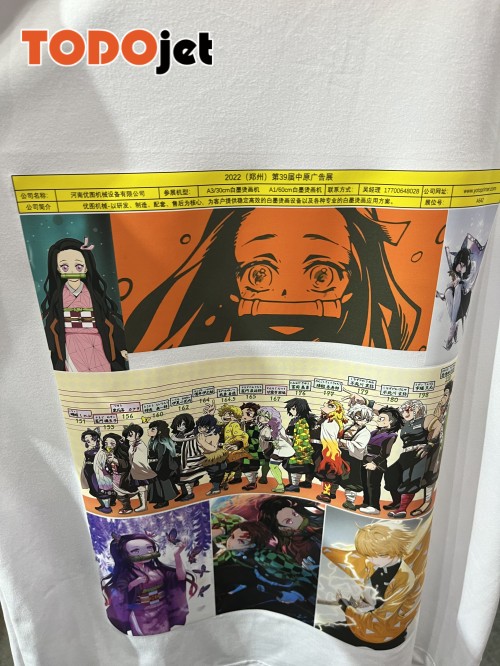

Step 3: put the substrate and the printed heat transfer film on the pressing machine, and stamp the pattern

Step 4:Tear off the heat transfer film to complete the heat transfer